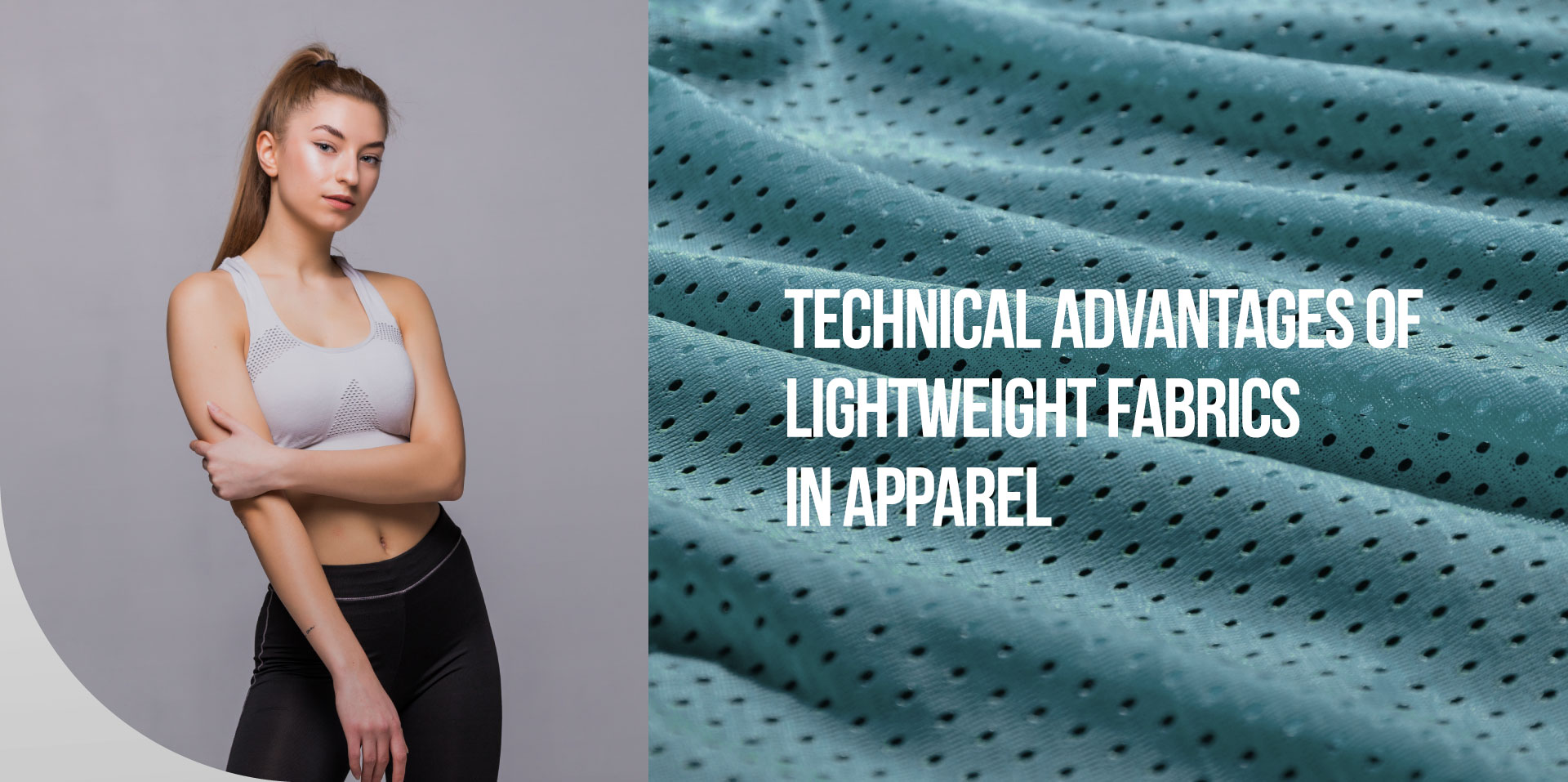

Technical Advantages of Lightweight Fabrics in Apparel

Performance, comfort, and sustainability are the three major consumer priorities driving the demand for lightweight fabrics. Athletes and everyday users alike seek garments that enhance mobility, regulate temperature, and minimize environmental impact. As a result, innovative textile technologies are accelerating the development of fabrics that are lighter, stronger, and more versatile than ever before.

This article introduces lightweight fabrics and explores why they matter for both consumers and manufacturers. From technical benefits to real-world applications, you’ll learn how lightweight fabrics are revolutionizing everything from athletic wear to medical apparel.

What Are Lightweight Fabrics?

Lightweight fabrics are textiles characterized by a low fabric density and a high strength-to-weight ratio. In other words, these materials weigh less without sacrificing durability or functionality. This combination of properties makes lightweight fabrics an ideal choice for clothing that demands both performance and comfort.

Common Fiber Types

Some of the most popular fibers used to create lightweight fabrics include:

- Nylon: Known for its strength, quick-drying capabilities, and resistance to abrasion.

- Polyester Blends: Widely used in sports and activewear for moisture-wicking and breathability.

- High-Tech Synthetics: Specialized fibers like ripstop nylon, spandex, or aramid blends designed for extreme conditions.

- Natural Fibers (e.g., Bamboo): Bamboo-based fabrics offer a combination of softness, breathability, and sustainability.

Key Characteristics

- Durability: Despite weighing less, many lightweight fabrics are engineered to withstand wear and tear.

- Drape: The low density allows garments to fall smoothly and comfortably along the body.

- Breathability: Advanced weaving techniques improve airflow, making these fabrics ideal for high-performance activities.

- Ease of Care: Lightweight fabrics often dry quickly and resist wrinkles, lowering maintenance needs.

Key Technical Benefits

The table below summarizes the core technical benefits of lightweight fabrics and how each feature enhances apparel performance:

|

Technical Benefit |

Description |

|

Soft Handfeel |

Lower fabric mass provides a softer, more flexible touch against the skin. |

|

Reduced Bulk |

Minimizes friction, allows easier movement, and improves layering potential. |

|

Advanced Fiber Structures |

Micro-gaps or special weaves enhance airflow and moisture-wicking properties for optimal breathability. |

|

Cooling Effect |

Faster sweat evaporation helps regulate body temperature, keeping wearers cool and comfortable. |

|

Insulation vs. Ventilation |

Engineered to trap warm air when needed or increase airflow in hot conditions, ensuring versatile thermal regulation. |

|

Layering Compatibility |

Perfect for all-season apparel; the lighter materials allow for multiple layers without excessive bulk. |

|

High-Tech Fibers |

Modern synthetics like ripstop nylon maintain exceptional strength despite reduced weight. |

|

Longevity |

Lightweight doesn’t have to mean fragile; advanced weaving and fiber technologies boost tear resistance. |

|

Flexibility |

Less restrictive materials that improve range of motion for athletic or everyday activities. |

|

Muscle Efficiency |

Reduced garment weight can decrease wearer fatigue, especially during prolonged or intense activities. |

|

Lower Shipping Costs |

Lightweight fabrics cut down on shipping weights, reducing the overall carbon footprint of transportation. |

Applications and Examples

- Sports and Activewear

From marathon running to team sports, lightweight fabrics have become a staple in performance clothing. Their ability to manage moisture, regulate temperature, and their innate lightness, makes them particularly valuable for endurance activities.

- Outdoor Gear

Jackets, backpacks, and even tents rely on lightweight materials for portability and packability. These fabrics balance the need for weather resistance with minimal bulk—crucial for hikers, campers, and travelers.

- Everyday Casualwear

For everyday T-shirts, dresses, and summer wear, lightweight fabrics provide breathability and comfort, especially in warmer climates.

- Travel Apparel

Quick-drying and easily packable, lightweight garments are perfect for frequent travelers who value efficiency. They take up less suitcase space and reduce the overall load.

- Medical Apparel

In medical settings, lightweight fabrics contribute to both comfort and hygiene. Breathable, stretchy materials reduce discomfort for patients and healthcare providers, while also helping uniforms stay fresher for longer.

Mini Case Study - A Valuable Lesson Learned

In one notable project, we developed a woven jacquard waistband for performance sportswear designed for men’s shorts and pants. Although our initial samples demonstrated the potential for a lightweight design, the project's cost constraints and high-volume production requirements led the brand to explore alternative proposals. One such approach used a thinner yarn to achieve the desired lightness, but it demanded additional specialized machinery that ultimately couldn’t meet production capacity. The result was a waistband that, while lightweight, lacked the necessary structural support—causing the garments to drape and wrinkle on retail hangers.

This experience taught us an invaluable lesson: lightweight design in sportswear must be balanced with robust, well-engineered solutions. It reinforced our commitment to integrating advanced elastic technologies that not only reduce weight but also maintain the rigidity and support essential for both functionality and aesthetics. At ECI, we leverage this insight to ensure our products deliver optimal performance, durability, and design excellence in every application.

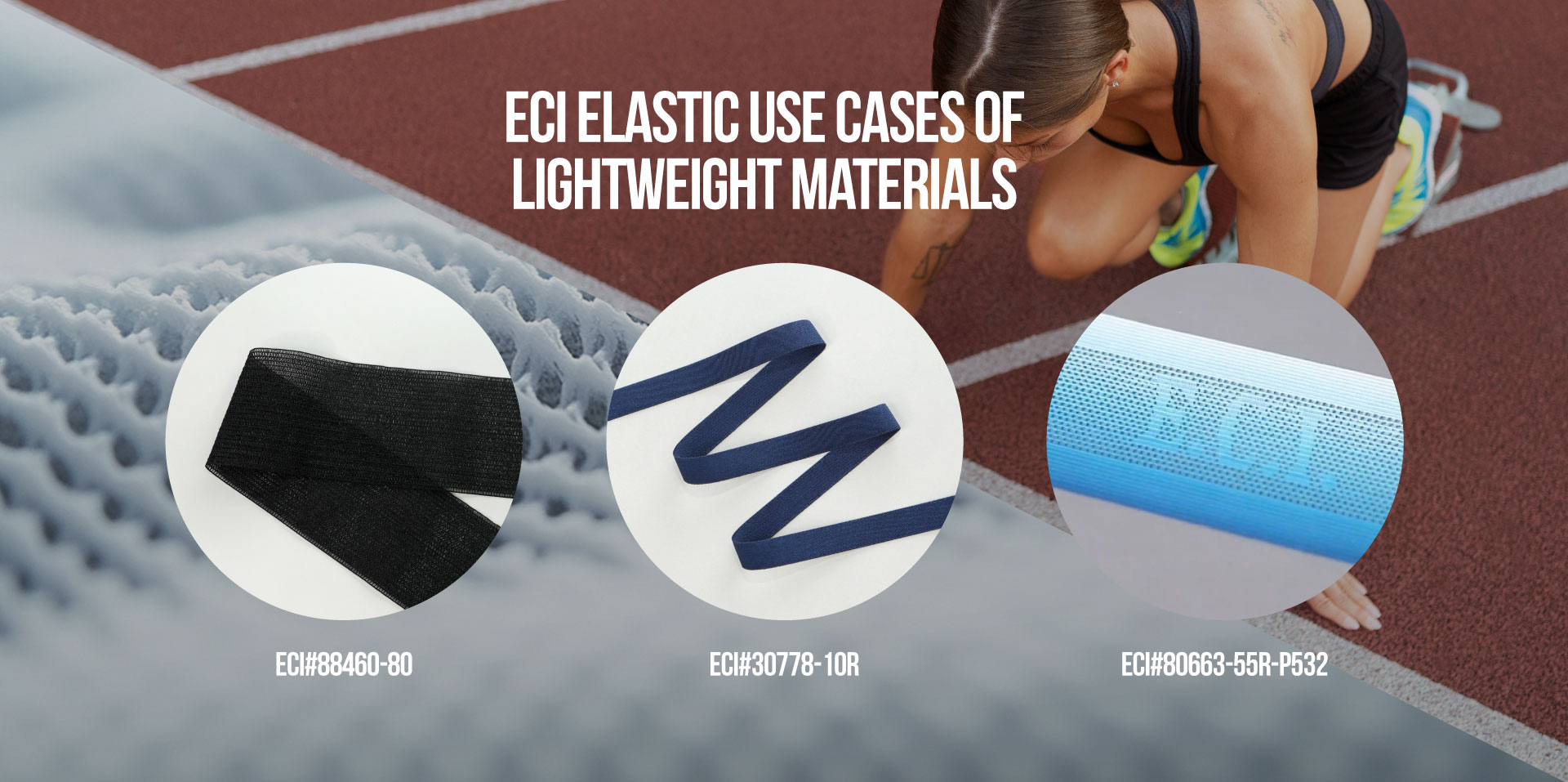

ECI Elastic Use Cases of Lightweight Materials

At ECI Elastic, we’re continually exploring ways to harness the benefits of lightweight fabrics in our product offerings. Whether integrating ultralight elastic tapes into medical apparel or developing high-performance trims for activewear, our commitment to innovation drives us to push the boundaries of comfort, functionality, and sustainability.

The following are just some of our examples of lightweight elastic tape solutions

- Inner Elastic:88460-80

- Back Neck Tape:30778-10R

- Decorative Tape:80663-55R-P532

Stay tuned for more details on how ECI Elastic continues to drive apparel innovation with the latest in lightweight fabric technologies. Let us know if you’re interested in lightweight elastic tape solutions for your next project.