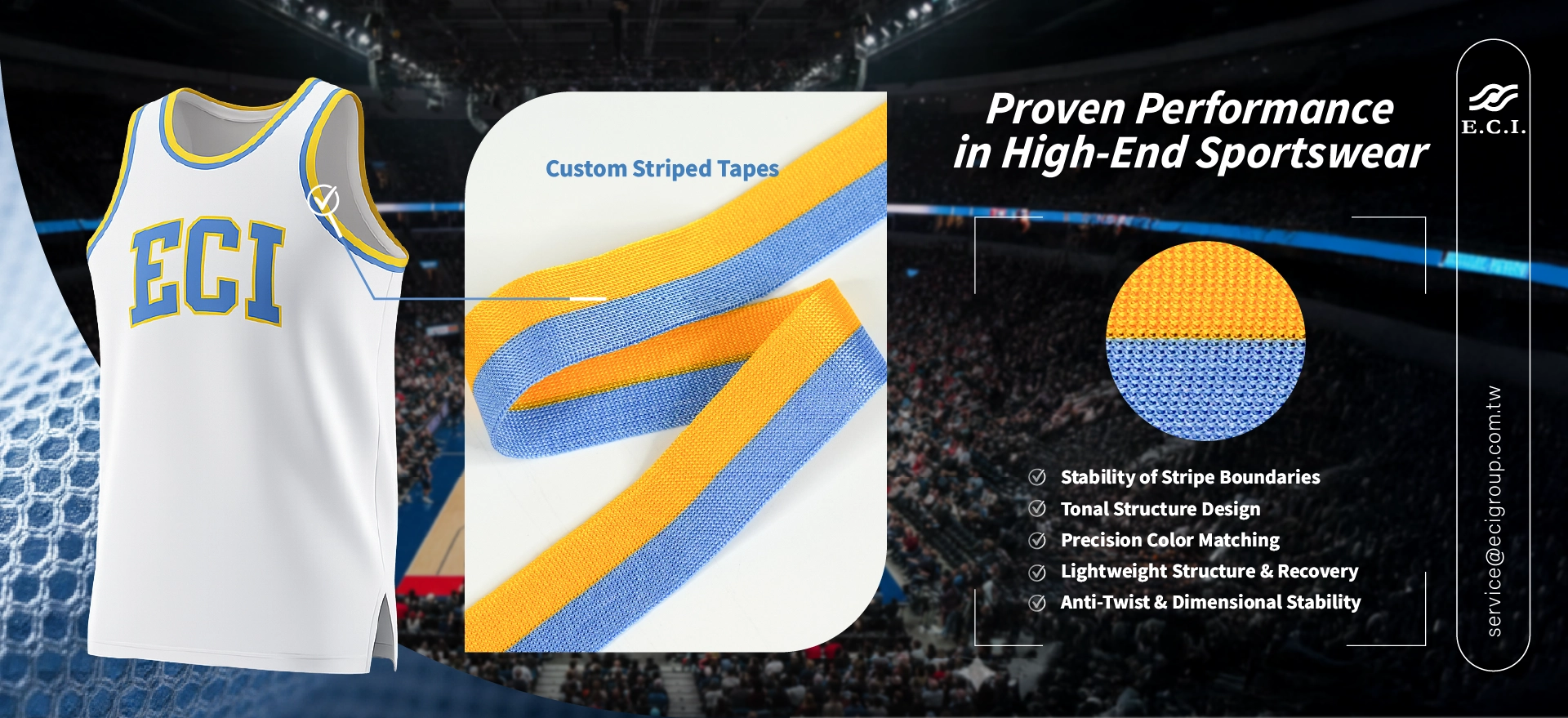

Color as Brand Language: Engineering Structure and Precision Palette for High-Recognition Custom Striped Tapes

In the design of apparel and functional textiles, colors and lines are more than just visual elements—they represent a synthesis of structural design and manufacturing stability. Beyond the primary fabric, trims like webbing and tapes are often the critical details that determine overall quality, durability, and brand consistency.

ECI specializes in the R&D and manufacturing of high-specification Custom Striped Tapes. Through mature weaving techniques, stable dyeing control, and a precision color-matching system, we help brands effectively transform design concepts into mass-producible, replicable product solutions.

Proven Performance in High-End Sportswear

ECI striped tapes have been implemented within the official NBA jersey system, passing rigorous verification for high-intensity wear, frequent laundering, and prolonged stretching, demonstrating superior and stable physical properties.

- Stability of Stripe Boundaries Utilizing specialized weaving structures, we effectively control yarn arrangement and tension distribution. This ensures sharp, clear stripe boundaries that maintain their integrity without bleeding or blurring, even under repetitive stretching.

- Tonal Structure Design By adjusting stripe width ratios, rhythmic arrangements, and weaving parameters, we create depth within a single-color palette. This balances visual dimension with brand color consistency, ideal for high-recognition uniforms and professional sportswear.

- Precision Color Matching Developed based on Pantone standards and supported by internal color management protocols, our process minimizes color variance across different materials and batches, ensuring long-term consistency and traceability.

- Lightweight Structure & Recovery While maintaining structural strength, we optimize weaving density and yarn configuration to provide softness and fit. The tapes retain excellent recovery performance, meeting the demands of athletic movement and long-term wear.

- Anti-Twist & Dimensional Stability Our tapes possess exceptional anti-twist properties and dimensional stability. Suitable for necklines, cuffs, side seams, and structural reinforcements, they maintain a flat appearance and reduce the risk of deformation over time.

From Professional Sports to Daily Brand Wear

Whether for corporate uniforms emphasizing a professional image or team apparel fostering cohesion, for detail-oriented designers, the clarity of every line and the saturation of every hue are key to brand identity.

ECI custom striped tapes are engineered for high-standard design requirements. We understand a designer’s insistence on detail and utilize mature technology to help brands overcome manufacturing limitations, fully realizing their creative vision.

ECI Custom Striped Tapes: Technical Advantages

- Versatile Configurations: Multiple widths and structural options available based on application needs.

- Refined Tonal Design: Support for fine-tuned ratios and rhythms in tonal stripe variations.

- High Color Fastness: Excellent washing colorfastness, suitable for environments requiring long-term, repeated laundering.

- Stable Manufacturing: Consistent processes conducive to mass production and rigorous quality control.

Let Color Become Your Brand Language

Seeking the perfect balance between design freedom and production quality? ECI integrates textile expertise with rigorous craftsmanship to provide high-stability webbing solutions. From color to structure, we help brands implement a consistent and competitive visual identity in every inch of detail.

Contact the ECI development team today. Let us transform colors and lines into brand language with high-impact recognition.