Research & Development

Innovation in Every Thread: ECI’s R&D Commitment to the Future of Narrow Fabrics

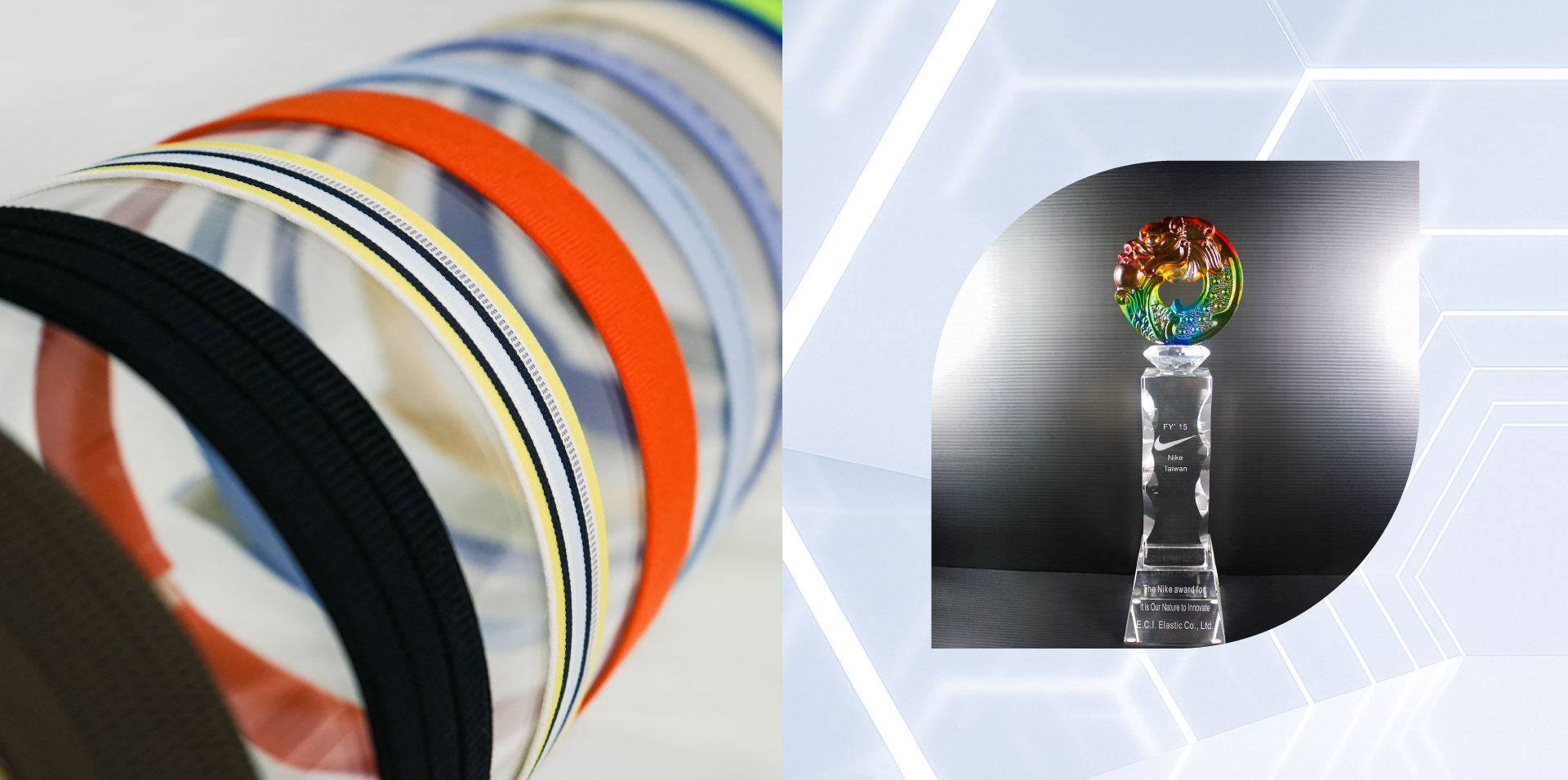

Though elastic narrow fabrics represent a small fraction of apparel, intimates, and footwear, they serve as essential components that can make or break finished garments and shoes. Depending on design and craftsmanship, these specialized trims may be visible or work invisibly—but they always matter. The right narrow fabric elevates performance, enhances aesthetics, and delivers lasting value to your product. This level of precision and innovation requires continuous research and development to push the boundaries of what's possible.

At ECI Elastic, research and development has been our foundation since day one. Founded in 1974, we've spent over 50 years advancing the quality, performance, and sustainability of narrow fabrics. In 2000, we formalized our commitment to innovation by establishing a dedicated R&D center, complete with testing laboratories that align with international ISO and AATCC standards. Today, with multiple facilities across Asia, we support brand partners and Tier 1 manufacturers with practical innovation at every stage of product development.

A Long-Term Commitment to Innovation

From our early adoption of European looms to in-house finishing processing and GRS certification, R&D has guided ECI's growth. Our R&D center, certified testing labs, and production-integrated design processes help deliver functional, scalable results across apparel categories.

With innovative ideas and quick development turn time, highlights include the 2015 Nike TWLO Innovation Award and ongoing partnerships with brands seeking new solutions to design, performance, and sustainability challenges.

Focused on What Matters Most

Our R&D efforts address the real-world needs of our partners:

- Narrow Fabric Engineering: Creating trims with precise performance across elastic and non-elastic applications.

- Sustainable Materials: Innovating with recycled, bio-based, and low-impact inputs.

- Performance and Functionality: Improving durability, stretch, and recovery for active, intimate, and outdoor wear.

- Finishing and Decoration: Expanding what's possible with print, emboss, and coating technologies.

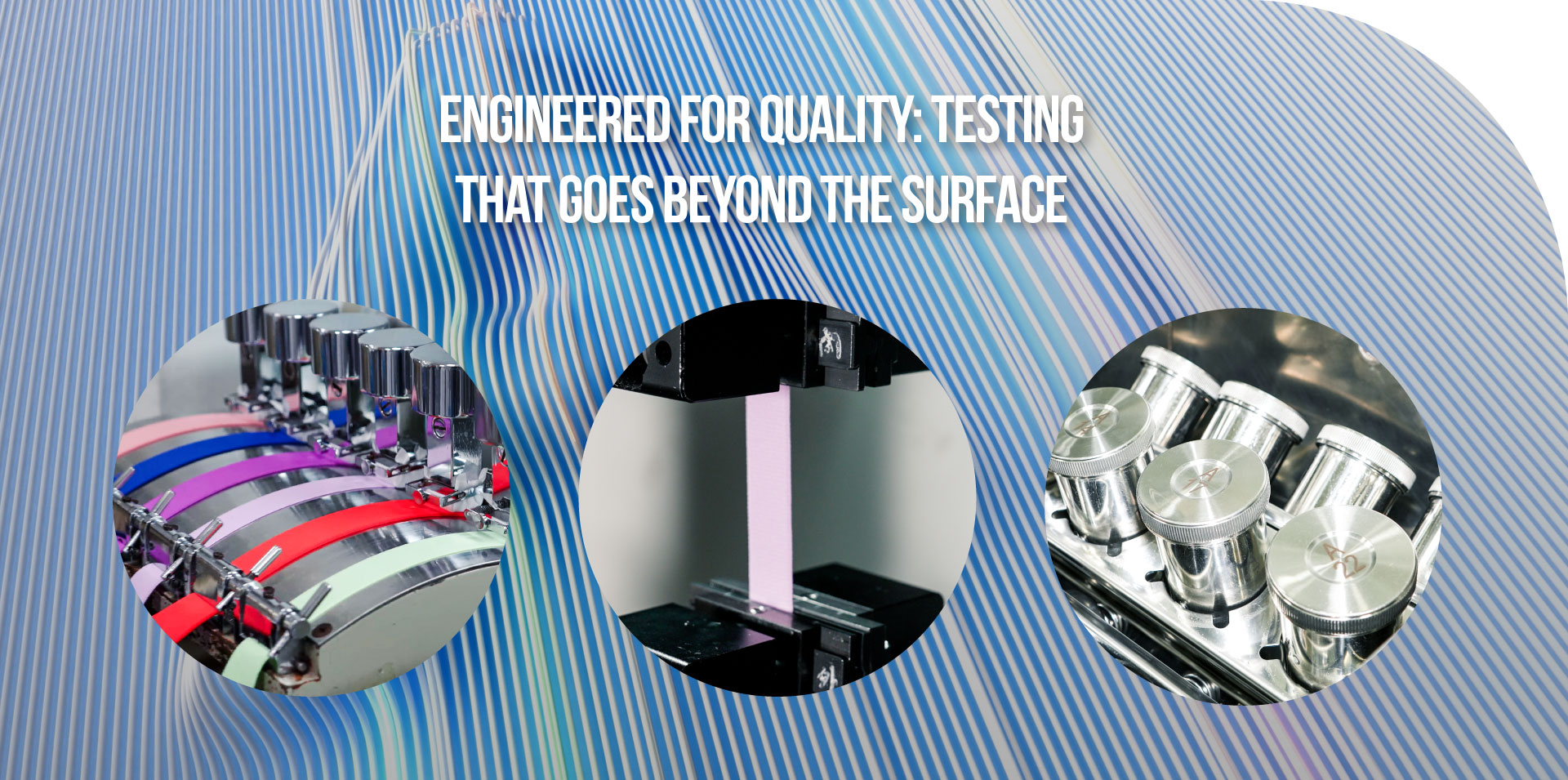

Engineered for Quality: Testing That Goes Beyond the Surface

At ECI, quality assurance goes beyond surface inspection. While manual appearance checks remain important, we rely on precision testing equipment to validate the physical performance of every elastic tape. Our in-house labs evaluate critical attributes including colorfastness to washing, resistance to crocking, dimensional stability, and long-term wash durability. These comprehensive tests ensure that every trim meets brand expectations—not just in initial appearance, but in how it performs through repeated wear, care, and time.

Recent Innovations in Sustainable Trim

Rethinking Stretch: Mechanical Elasticity Without Elastane

The recycling complications of elastane are well known—even 2–3% can make a garment difficult to recycle. ECI’s R&D team tackled this challenge with a mechanical stretch trim made entirely from recycled polyester. Using specialized yarn construction and weaving methods, we achieve controlled stretch performance without chemical elastomers—helping brands meet recyclability goals without giving up function.

Acetate Film-Free Drawcord Tips

Traditional acetate-tipped cords are durable—but create mixed-material waste. Our new Film-Free Drawcord Tipping eliminates acetate entirely, using a heat-press method with bluesign®-certified resins. The result: a mono-material drawcord that looks and performs like standard solutions, but is fully recyclable and cuts plastic waste by 15–20%.

These breakthroughs are part of a broader strategy: to design trims that support circular manufacturing without sacrificing quality or design flexibility.

Why It Matters for Our Clients

- Faster Development Cycles: Integrated design and production help reduce sample lead times.

- Reliable Performance: Materials are engineered to meet stringent specs for stretch, strength, and finish.

- Compliance Built In: We design with ISO 9001, OEKO-TEX®, Higg Index, GRS, and other standards in mind—helping streamline your compliance reviews.

Open, Collaborative Development

We work side-by-side with global brands, technical suppliers, and academic partners to bring new materials and trims to market. Whether you’re refining an existing design or prototyping something new, we offer shared development resources to help bring ideas to life.

Built to Move Quickly

With R&D embedded across multi-locations, we support local execution and global scale. Vertical integration—from yarn prep to packaging—ensures quality and traceability across every touchpoint.

Innovation, Validated

- 2024: GRS certification at ECI Vietnam

- 2023: BVE3 Chemical Management Platform membership

- 2020: Exclusive elastic supplier for adidas' performance masks

- 2015: Nike TWLO Innovation Award

- 2014: ECI trims featured in World Cup-winning football kits

Have a product challenge or sustainability goal? Get in touch with our team to explore what’s possible with ECI R&D.