Denier and Weight in Bra Strap Manufacturing

If you've ever tried to spec a bra strap and felt lost in a sea of numbers—denier, DPF, GSM, grams-per-meter—you're not alone. Even people who live and breathe textiles can get tripped up by how these terms connect. So let's slow it down and make this simple, practical, and newbie-friendly. By the end, you'll know exactly what to ask for, what to measure, and how to trade off softness vs. support without guesswork.

The two numbers that do most of the heavy lifting

When you're designing or sourcing bra straps, two ideas matter a lot:

- Denier — a property of the yarn

- Weight — a property of the finished strap

Think of denier as the "thickness/heaviness" of the thread your strap is made from, and weight as how hefty the strap itself is per length or area.

They're related, but not the same: you can use fine yarns to make a heavy strap (tight, dense construction), or heavier yarns to make a surprisingly light strap (open construction). Knowing both lets you balance comfort and support.

What Is Denier, Really?

Denier (D) tells you how many grams 9,000 meters of a yarn weigh.

- If 9,000 meters weigh 70 grams, that's 70D.

- If they weigh 100 grams, that's 100D.

Two quick cousins:

- tex = grams per 1,000 meters

- dtex = grams per 10,000 meters

If you ever need to convert:

- denier ≈ dtex × 0.9

- denier = tex × 9

You'll also hear DPF (denier per filament), which is simply:

DPF = total denier ÷ number of filaments

Why care? Because DPF shapes the hand feel. Imagine a bundle of hair: lots of very fine strands = silky; fewer thick strands = firmer, a little "grabbier." In yarn terms, the same overall denier can feel very different depending on the filament count inside it. Lower DPF (more, finer filaments) tends to feel smoother on skin—great for satin-face straps.

What is strap weight, and how do we describe it?

Weight tells you how heavy the finished elastic is. For straps, it's often measured two ways:

- g/m (grams per meter) – great because straps are sold by length.

- GSM (grams per square meter) – helpful if you want to compare to other fabrics or log data in a lab-friendly way.

They convert easily using the strap width.

- If the strap width is W (in meters), then:

g/m = GSM × W

GSM = (g/m) ÷ W

Quick width conversions:

- 10 mm = 0.010 m

- 12 mm = 0.012 m

- 15 mm = 0.015 m

- 20 mm = 0.020 m

Example

A 12 mm strap (that's 0.012 m) weighs 7 g/m.

GSM = 7 ÷ 0.012.

Let's do it carefully:

- 0.012 × 500 = 6

- 0.012 × 583 = 6.996

- 7 ÷ 0.012 ≈ 583.33 GSM (about 583 GSM).

No need to memorize: just keep the width in meters and the simple formulas above.

Fibers You'll See in Straps (and Why They're Used)

Most quality bra straps are blends of a strong, abrasion-resistant filament (like nylon or polyester) with spandex (also called elastane) to provide stretch and recovery.

- Nylon (6 or 6.6) – soft, strong, great abrasion resistance; easy to tune into a silky hand with low DPF yarns.

- Polyester – a little crisper than nylon in similar constructions; tends to hold color better under light/UV and wet conditions; useful for swim or outdoor use.

- Spandex – the engine of stretch. Available in different deniers (you'll often see 40D, 70D, 105D, etc.). "Bare" or "covered" spandex changes how the strap behaves and feels. Covered spandex can improve stability and surface quality.

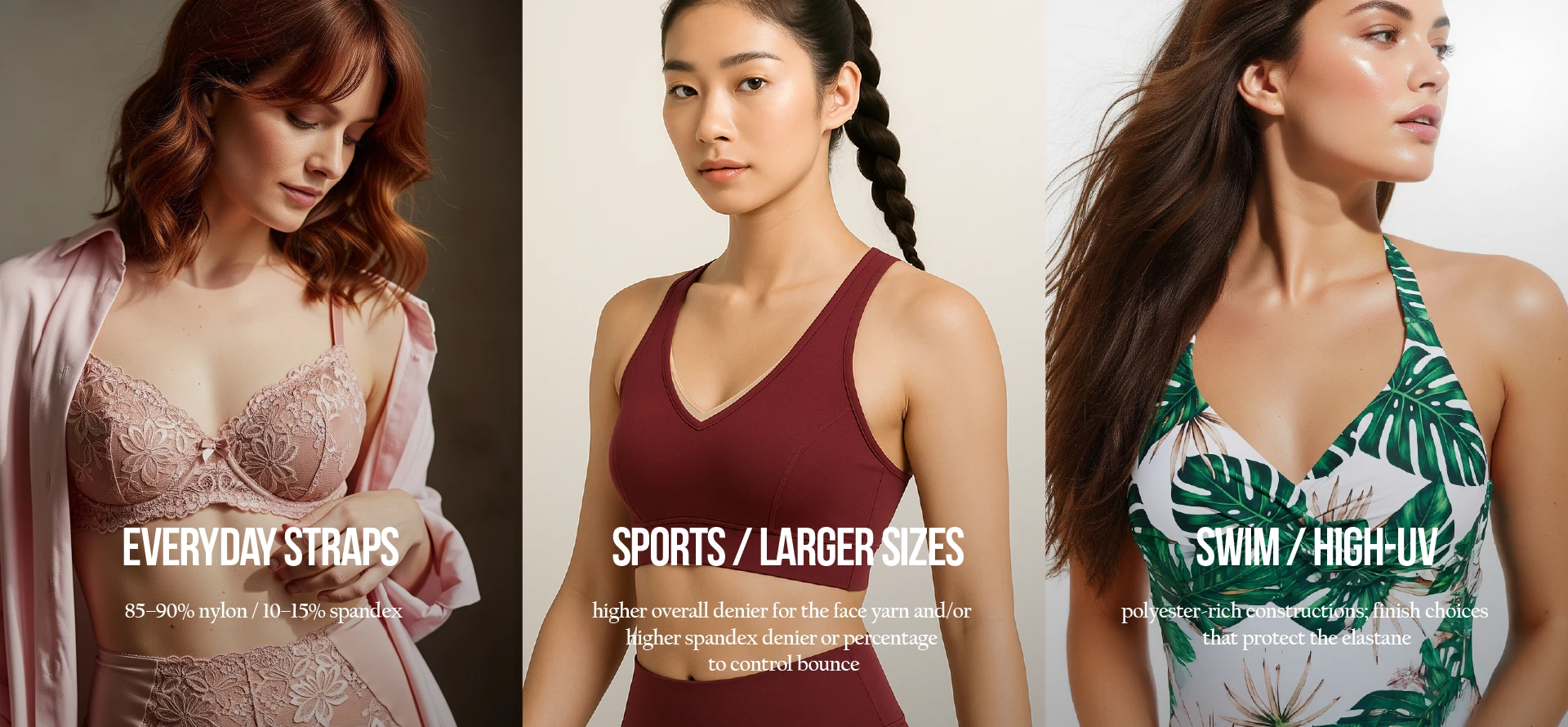

Common starting points (you'll tune these with your vendor):

- Everyday straps: ~85–90% nylon / 10–15% spandex

- Sports / larger sizes: higher overall denier for the face yarn and/or higher spandex denier or percentage to control bounce

- Swim / high-UV: polyester-rich constructions; finish choices that protect the elastane

Remember, the exact percentages matter less than what performance you want: comfort against skin, target stretch (how far it goes), recovery (how well it snaps back), and long-term durability.

Construction matters (a lot)

Denier tells you about yarn; construction tells you how those yarns are arranged.

- Tighter, denser constructions (woven or knit) generally increase stability and durability and can carry sliders and rings with less "creep."

- Looser or softer constructions can feel great but may stretch more under load and move more under hardware.

Face and back finishes also matter:

- Satin face for a smooth, elegant look and skin contact.

- Brushed backs for a velvety touch (less chance of chafing).

- Silicone lines or textures add friction to help straps stay put (handy for sports or slope-shouldered fit challenges).

How denier and weight translate to real-world performance

Comfort & hand feel

If you want a strap that feels silky against the skin, start with lower DPF yarns on the face side—those are yarns made of many very fine filaments, which naturally feel smoother. Pair that with a soft finish on the inside: brushed backs reduce friction, and slightly rounded edges help prevent that sharp "edge bite" feeling over a long day.

Support & durability

For a strap that works harder—think larger cup sizes or high-impact movement—lean into higher yarn deniers and a denser construction. Heavier, tighter builds resist abrasion better and hold their shape under hardware, so the strap keeps doing its job even after lots of wear and adjustment.

Stretch & recovery

How a strap stretches and snaps back is mostly about the spandex: its denier, how much of it you use, and whether it's bare or covered inside the structure. Set a clear target for elongation—around 85–100% is typical for everyday comfort, while firmer support lives a bit lower—and define how much "set" you can accept after repeated stretch cycles (that's the small amount of permanent length the strap might keep).

Hardware grip (no slipping)

To keep sliders and rings from creeping, a little more substance goes a long way. Slightly higher grams-per-meter combined with a smarter surface—subtle texture or a silicone line—helps the hardware grip so your strap stays exactly where you dial it in.

Common myths (let’s clear these up)

"Higher denier always means a stiffer, harsher strap."

Not necessarily. Higher denier yarns can still feel great if the DPF is low (many fine filaments) and the surface is finished well (satin face, brushed back). Construction and finishing are huge.

“Weight alone tells me how supportive a strap will be.”

Weight helps, but spandex setup (denier, % content, bare vs. covered) and construction determine how the strap stretches and snaps back. Two straps with similar g/m can perform very differently.

"If I want zero slippage, I should just add silicone."

Silicone lines or dots help, but the best results come from silicone + appropriate g/m + surface texture + hardware pairing. It's a system.

A fast path to the right sample (how to brief us)

When you send a brief, try this structure:

- Use case: "Everyday T-shirt bra" or "High-impact sports bra (E+ sizes)."

- Feel: "Silky face, soft back," or "Smooth but firm."

- Stretch target:

- Everyday bras: "Elongation ~50–90%" (for comfort and minimal movement)

- Sports bras: "Elongation up to 150%" (for range of motion and pressure distribution during high-intensity activities)

- Bra straps: "Elongation 70–90%" (to provide support and prevent sagging

- Slip control: "Minimal slider creep; okay to add silicone lines."

- Weight range: Provide a g/m target or range, and we'll translate it to GSM for the lab ticket.

- Color/fastness notes: If UV, sweat, or swim is relevant, say so up front.

- Testing: Tell us how you'll approve (weight, cyclic stretch/recovery, any extras like tensile/abrasion/lightfastness).

From there, we’ll pick yarn deniers (and DPF), construction, and spandex configuration to hit your numbers—then we’ll give you the data so you can compare options apples-to-apples.

Mini glossary (save this)

- Denier (D): grams per 9,000 m of yarn. Bigger number = heavier yarn.

- DPF: denier per filament; lower DPF = finer filaments = smoother feel.

- g/m: grams per meter of finished strap (great for purchasing and QC).

- GSM: grams per square meter; useful for lab comparisons.

- Bare vs. covered spandex: covered can feel smoother/more stable; bare can feel livelier—depends on construction.

- Set: the percentage of length a strap "keeps" after repeated stretch cycles (lower is better).

The bottom line

- Denier helps you tune feel and durability through yarn choice (and DPF).

- Weight (g/m and GSM) helps you control the finished strap's behavior—how it carries hardware, how substantial it feels, and even how it drapes.

- Construction + spandex setup decide how the strap stretches and recovers, which is what customers actually feel when they put the bra on.

If you’re just getting started, pick a clear use case, set a realistic stretch window, and specify the feel you’re after. Ask your manufacturing partner for two to three contrasting samples (e.g., low-DPF silky everyday, firmer sport build, and a polyester-leaning outdoor option). Compare them with the same test method and the same hardware. You’ll quickly see how denier, DPF, weight, and construction work together—and you’ll land on the right strap with fewer revisions.