Specification

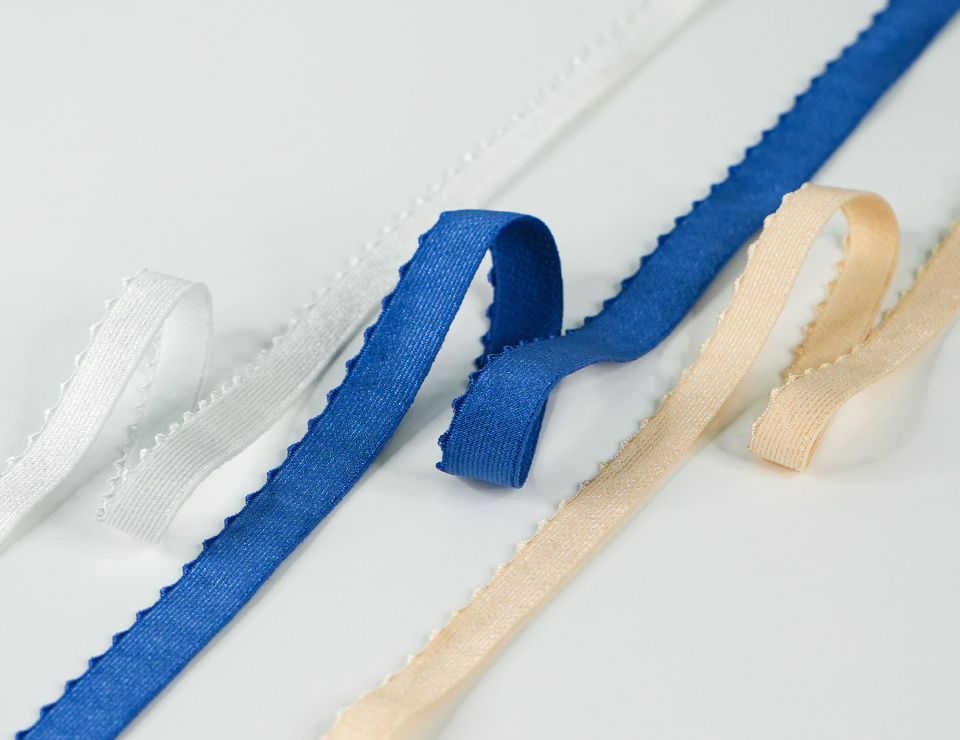

Product Type: Woven elastic tape

Item number: 33H37-12M

Aesthetic: skin friendly

Material Content Group: blend nylon/elastane

Color: Solid Color

Application: binding tape

Size: 1/2 inch

Ideal for: lingerie (intimate apparel)

Description: Woven elastic tape 33H37-12M features skin friendly aesthetic and is created with blend nylon/elastane. It comes in solid color and is commonly used for binding tape. The general size is 1/2 inch and is ideally designed for use in lingerie (intimate apparel).

Bias Binding Tapes

Bias binding tape is a versatile decorative and functional trim that adds refined finishing touches to garment edges while providing structural support. Sewn along necklines, armholes, hemlines, and seam edges, it delivers a polished aesthetic that elevates design while preventing fabric fraying and maintaining edge stability. Available in woven construction with excellent drape and flexibility, bias binding tape follows curved edges seamlessly thanks to its diagonal grain orientation. Our tapes come in solid colors and custom color-matching options to complement or contrast with garment fabrics. From classic nylon/elastane blends to specialized skin-friendly formulations, we offer both stock and custom solutions tailored to your design vision and production requirements.

Wholesale Bias Binding Tape Manufacturer

As a vertically integrated bias binding tape manufacturer, our production process gives us complete control over every step—from yarn selection through weaving, dyeing, finishing and packaging. We use precision weaving equipment and rigorous quality-control systems to ensure each bias binding tape delivers consistent elasticity, superior drape, and long-lasting color vibrancy. Materials are engineered to maintain their appearance and performance through repeated washing and wear. Our teams work closely with customers to develop customized binding tapes that align with specific design requirements, including width specifications, color matching, aesthetic finishes, and material blends optimized for both function and visual impact.

Technical Specifications

| Specification | Standard range | Premium/additional options | Custom available |

|---|---|---|---|

| Tape width | 3/8 in to 5/8 inch (9.5–16mm) – the most common sizes for edge finishing and binding applications | Narrower or wider widths for specialized design elements | Yes |

| Material composition | Nylon/elastane blend | Polyester/spandex blends, satin finishes, matte finishes, skin-friendly formulations | Yes |

| Stretch capacity | Low to medium stretch (50–90%) – suitable for edge finishing with controlled give | Higher stretch formulations for performance applications (100-150%) | Yes |

| Aesthetic/stability | Good stability with smooth drape and excellent edge-following properties | Enhanced skin-friendly finishes, premium color saturation, contrast piping effects | Yes |

| Color options | Solid colors: black, white, nude tones | Custom Pantone color matching, contrasting colors for visual pop | Yes |

| Minimum order | 10,000 meters | Reduced minimums for selected styles | Negotiable |

| Lead time | 2–3 weeks | 3–4 weeks for custom specifications | Longer for complex solutions |

Quality Certifications

All bias binding tapes are manufactured to OEKO-TEX Standard 100, ISO 9001:2015 quality management standards, and meet international textile safety standards for direct skin contact applications.

How to Order

Our ordering process is simple and efficient, ensuring you receive quality products that meet your specifications.

Initial Consultation

Contact our sales team with your specifications, including width requirements, color preferences, aesthetic finishes, and quantity estimates for a comprehensive project assessment.

Sample Development

Our engineering team creates precision prototypes based on your exact requirements, typically delivered within 14-21 business days for thorough evaluation and testing.

Material & Design Selection

Choose from our extensive range of premium binding tape finishes, stretch configurations, and color matching services, including Pantone color matching for brand consistency and contrasting accent options.

Quote & Production Timeline

Receive detailed pricing based on specifications, quantities, and delivery requirements with transparent lead times and flexible payment terms for your business needs.

Production & Quality Control

Your order enters our ISO-certified manufacturing environment with regular quality checkpoints, progress updates, and comprehensive testing throughout the production cycle.

Top Questions About Our Bias Binding Tape

Frequently asked questions about our products and services.

At ECI, we offer binding tapes in continuous form by the yard. However, we understand that maintaining curve-hugging flexibility is essential for details like necklines, armholes, and other shaped seams. Bias binding tape, with its 45-degree orientation, naturally stretches and conforms to curves without puckering, which is why it's often used in these areas. While our tapes are woven straight, we help customers achieve similar smooth results by selecting the right materials, finishes, and softness to suit curved applications. We also support product development by providing sample yardage for trial sewing and fit testing before mass production. Once everything is dialed in and approved, full-scale manufacturing can proceed with confidence.

Material composition directly influences performance and feel. Nylon/elastane blends offer excellent stretch recovery and a smooth, sleek hand-feel ideal for athletic and intimate apparel. Polyester/spandex combinations provide durability with moderate stretch and a slightly firmer hand. Satin finishes create luxurious drape with soft, fluid feel, while matte finishes offer subtle appearance with excellent stability. Higher elastane content provides greater stretch and softer drape; lower percentages maintain structure and edge definition.

Width selection depends on garment type and desired visual impact:

● 3/8 inch (9.5mm): Delicate lingerie, lightweight blouses, subtle edge finishing

● 1/2 inch (12mm): Most versatile width for standard necklines, armholes, and hems across lingerie, activewear, and casual apparel

● 5/8 inch (15mm): Medium-weight garments, visible decorative binding, applications requiring more support

● 3/4–1 inch (19–25mm): Outerwear, heavy-duty applications, bold contrast effects

Lighter fabrics pair best with narrower widths; heavier materials benefit from wider tapes for visual balance and structural integrity.

Yes, we offer comprehensive color customization. Our Pantone color matching service ensures precise coordination with your fabric for seamless integration. Alternatively, contrasting colors create intentional visual pop—black binding on white garments, bright accents on neutral bases, or tonal variations for subtle dimension. We develop custom color combinations aligned with seasonal trends, brand palettes, or specific design concepts for both invisible finishes and bold statements.

Our binding tapes are engineered for durability through:

● Colorfast dyeing: Heat-set dyes prevent fading, bleeding, or color transfer

● Premium elastane: Maintains recovery through hundreds of wash cycles

● Stabilized weave: Prevents edge fraying and maintains structural integrity

● Pre-shrunk finishing: Eliminates post-wash puckering

When properly attached and cared for, our tapes retain original appearance, stretch, and color vibrancy throughout the garment's lifecycle.

Yes, we offer specialized formulations for sensitive skin:

● OEKO-TEX Standard 100 certified: Free from harmful chemicals and irritating substances

● Hypoallergenic nylon/elastane blends: Minimize allergic reactions for intimate apparel

● Natural fiber alternatives: Spun-polyester or bamboo-blend options with controlled stretch

● Latex-free construction: No natural rubber latex, eliminating common allergens

● Smooth-finish options: Ultra-soft hand-feel reduces friction during extended wear

These options are ideal for lingerie, activewear, children's clothing, and medical garments. Our team can recommend the best formulation based on your application and target market needs.

Ready to Start Your Project?

Contact our manufacturing experts for custom quotes and sample development. We are committed to realizing your bias binding tape design vision with precision engineering and excellent quality.

Get Custom Quote