History

Our Heritage: The ECI Story

From our founding in 1974 as a small elastic manufacturer in Taiwan, ECI has grown into a global supplier of narrow fabrics with manufacturing facilities across the world's most strategic production hubs. Our history is a tapestry of innovation, strategic expansion, and enduring partnerships with brands who trust us for reliable sourcing and wholesale solutions.

Established E.C.I. ELASTIC CO., LTD.

Relocated to the current FuXing industrial location in ZhangHua county.

Imported European-made Guage15 pin high-speed needle loom.

Imported complete set of high-speed shuttle-less loom, Guage20 pin high-speed needle loom, and persistent dyeing and shaping machine to accommodate customer needs.

Imported Swedish-made Jacob Muller computer labeling machine and added to the production line to increase product diversity and variety.

Established Ying Shan CO., LTD. and tapped the market in various elastic yarn production.

Achieved 10 million meters per month in production volume, and reached into the Southeast Asian market.

- Lead in TQM management system.

- Promoted 5S activities.

- Lead in the computerization of management systems.

- Imported single-liquid silica gel processing equipment.

- Certified ISO 9001 product quality certification.

- Passed OEKO-TEX100 product quality certification

- Established best work relations with Dupont Taiwan.

- Set up research and development center, and testing laboratories with international certification standards.

- Achieved 13.5 million meters per month in production volume.

- Imported pattern-imprinting technology.

- Established Hong Kong and Indonesia branch companies (offices).

Lead in business strategy and goals management system.

- New facility for ZHUHAI E.C.I. ELASTIC CO., LTD. completed and ready to operate.

- Set up ShangHai office.

- Imported new computer labeling machine and new dyeing equipment.

- E.C.I. Taiwan achieved 15 million meters per month in production volume.

- Establishment of SUNPOLAR International Co.,Ltd.

- Imported cotton fabric machine equipments and heat imprinting technology.

- Achieved combined production volume of 20 million meters per month.

- Establishment of FOCUS UNDERWEAR ASSIST COMPANY (molded cups).

- Imported double-liquid silica gel processing equipment.

- Expanded R&D equipment and decreased sample developmental period by 40% to meet customer demands.

- Achieved combined production volume of 30 million meters per month.

- Set up Xiamen office.

Establishment of E.C.I. ELASTIC CO., LTD. (branch office in Lu-Kang, Changhua). Imported up-to-date dyeing equipments and innovative know-how to provide satisfactory products.

- New facility for Vietnam E.C.I. ELASTIC CO., LTD. completed and ready to operate.

- Increased production capacity to 20 million meters per month (E.C.I. Taiwan).

- Imported flexographic equipment, computerized jacquard looms and new machinery to provide various developments.

- Created international work-division strategy and achieved production capacity of 34 million meters per month (E.C.I. Taiwan, ZHUHAI and Vietnam).

- Broke ground for second plant of E.C.I. ELASTIC CO., LTD. (branch office) in order to increase capacity and improve the lead time of sample collection.

ECI receive Innovation Award from Nike TWLO.

ECI-VN accredited for VCA.

- Established 2nd ECI-VN mill and achieved production capacity of 50 million meter per month on 3 locations.

- Accredited for adidas/Natific mill and supplier CAP.

- Accredited for PUMA CAP.

- Received the honor of being the best business partner by NIKE.

- Received Self Laboratory Testing Accreditation by adidas.

- Passed Oeko-Tex 100 Yarn Quality Certification (E.C.I. Taiwan, ZHUHAI and Vietnam).

- Received a certificate of Higg FEM, earned recognition for having Great Environmental Management, Safety and Hygiene System.

- Establishment of VIET NAM SUN POLAR CO.,LTD.

- Received a certificate of SLCP, and earned recognition for having Social Labor Module Certification.

- Honored to be a part of National Face Mask Team, offering earloop of mask and webbing of protective clothing.

- Received the honor of being the long-term supplier by adidas.

- Be invited to do new earloop of mask co-development as an exclusive supplier of adidas’ mask.

- Approval from Ministry of Economic Affairs of action plan for Accelerated Investment by Domestic Corporations.

Received the laboratory accreditation by UA.

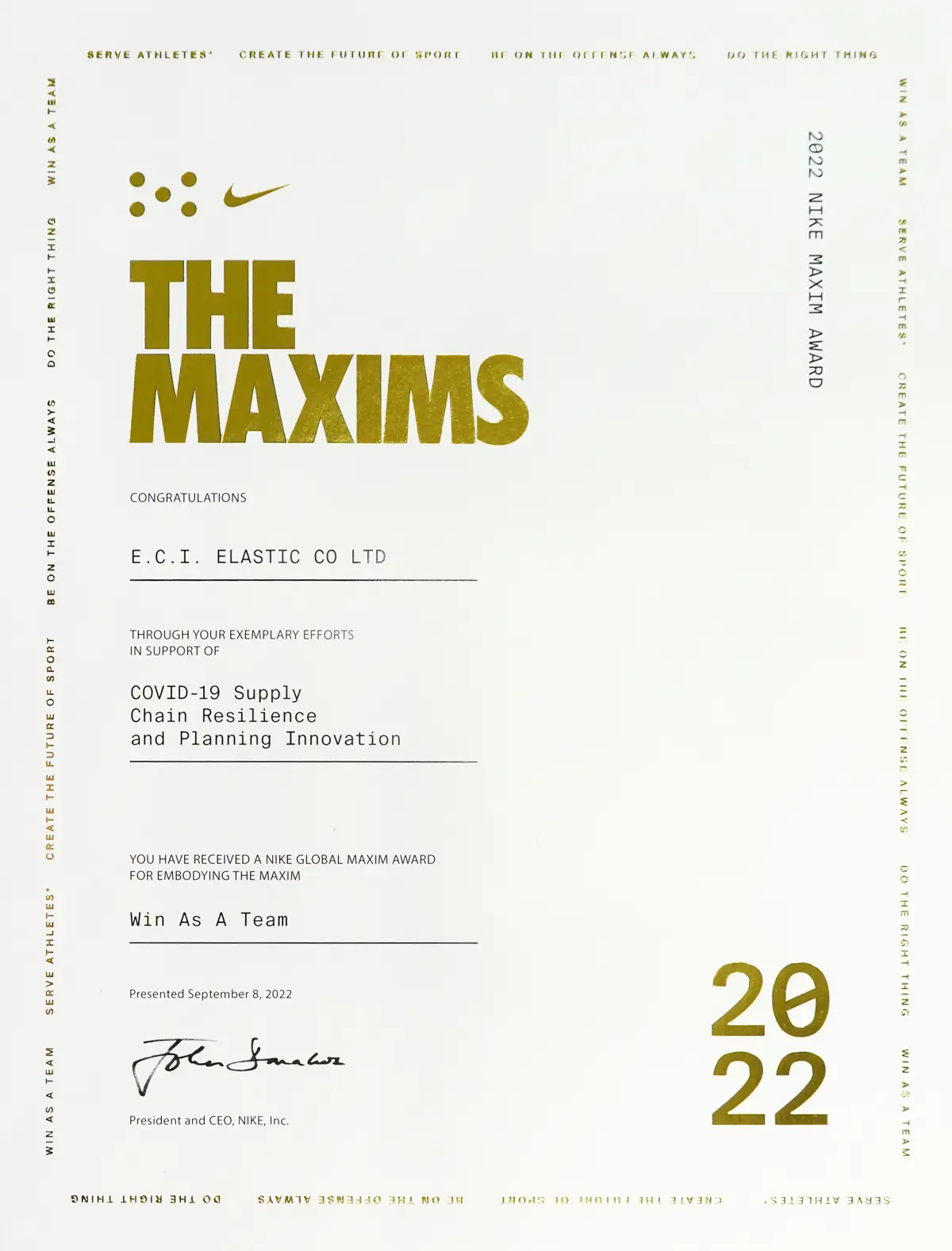

Received the Maxim Award "Win as a Team"

- Received a certificate of VF Factory Compliance Audit

- New facility for Taiwan E.C.I. ELASTIC CO., LTD. completed and ready to operate.

- Join the BVE3 Chemical Management Platform (a digital solution platform recognized by ZDHC)

Vietnam E.C.I. received GRS (Global Recycled Standard) Certificate

Zhuhai E.C.I. received GRS (Global Recycled Standard) Certificate

Taiwan E.C.I. received GRS (Global Recycled Standard) Certificate