Eco-Friendly Elastic Tape Trends for 2025

The demand for sustainable textiles has grown exponentially in recent years, driven by consumers and brands alike. As the broader fashion and textile industries embrace eco-friendly practices, elastic tape manufacturing is no exception. Once viewed as a minor component of garment construction, elastic tapes are now central to the sustainability conversation. In 2025, new materials, advanced techniques, and strategic practices are shaping a greener future for elastic manufacturing.

Recycled Materials: Closing the Loop

One of the most significant trends in sustainable elastic production is the use of recycled materials. By repurposing post-consumer and post-industrial waste, manufacturers are reducing their reliance on virgin resources.

- Recycled Polyester: Elastic tapes made with recycled polyester yarns are gaining popularity. These yarns are derived from PET bottles and textile waste, providing durability while reducing landfill waste.

- Recycled Nylon: Known for its strength, recycled nylon is becoming a staple in elastic tapes for sportswear and performance apparel.

- Closed-Loop Solutions: Scraps generated during the production process can now be reincorporated into new batches, reducing waste and creating a circular production model.

At ECI Elastic, we’ve been leveraging innovative recycling techniques to create elastic tapes that maintain their strength, elasticity, and aesthetic appeal while contributing to a circular economy.

New Yarn Developments: Sustainable and Functional

The introduction of advanced yarns is reshaping the elastic industry, enabling manufacturers to achieve both sustainability and performance.

- Bio-Based Yarns: Yarns derived from renewable sources, such as bio-nylon and bio-polyester, are leading the charge. These yarns not only reduce dependence on petroleum-based materials but also have a lower carbon footprint.

- Fancy Yarns from Scrap: Fancy yarns created from leftover textile scraps are now being used in decorative elastic tapes, offering a visually appealing and eco-friendly option for apparel designers.

By adopting these yarns, elastic manufacturers are not just enhancing the technical capabilities of their products but also catering to the growing consumer demand for greener alternatives.

Exploring Other Sustainable Yarn Options

Inspired by COP29, there is a renewed focus on discovering innovative materials and stronger incentives for using post-consumer or post-industrial recycled materials in elastic textiles. ECI Elastic is at the forefront of this shift, collaborating with raw materials suppliers to introduce new sustainable yarns—such as paper yarn and biomass nylon yarn—into our product lines.

Paper Yarn

Paper yarn is a cutting-edge option that demonstrates lightweight durability and biodegradability. While not used for traditional elastic purposes, ECI Elastic incorporates paper yarn into non-elastic drawcords as well as knit and woven structures. This allows us to expand our sustainable offering without compromising on performance.

- Supplier:ABACELL

- Representative Product Items:

- Drawcords: 71167-8.5, 71158-2, 71159-2, 78212-13

- Knit Tape: 41018-38

- Woven Tape: 22470-15, 22469-15

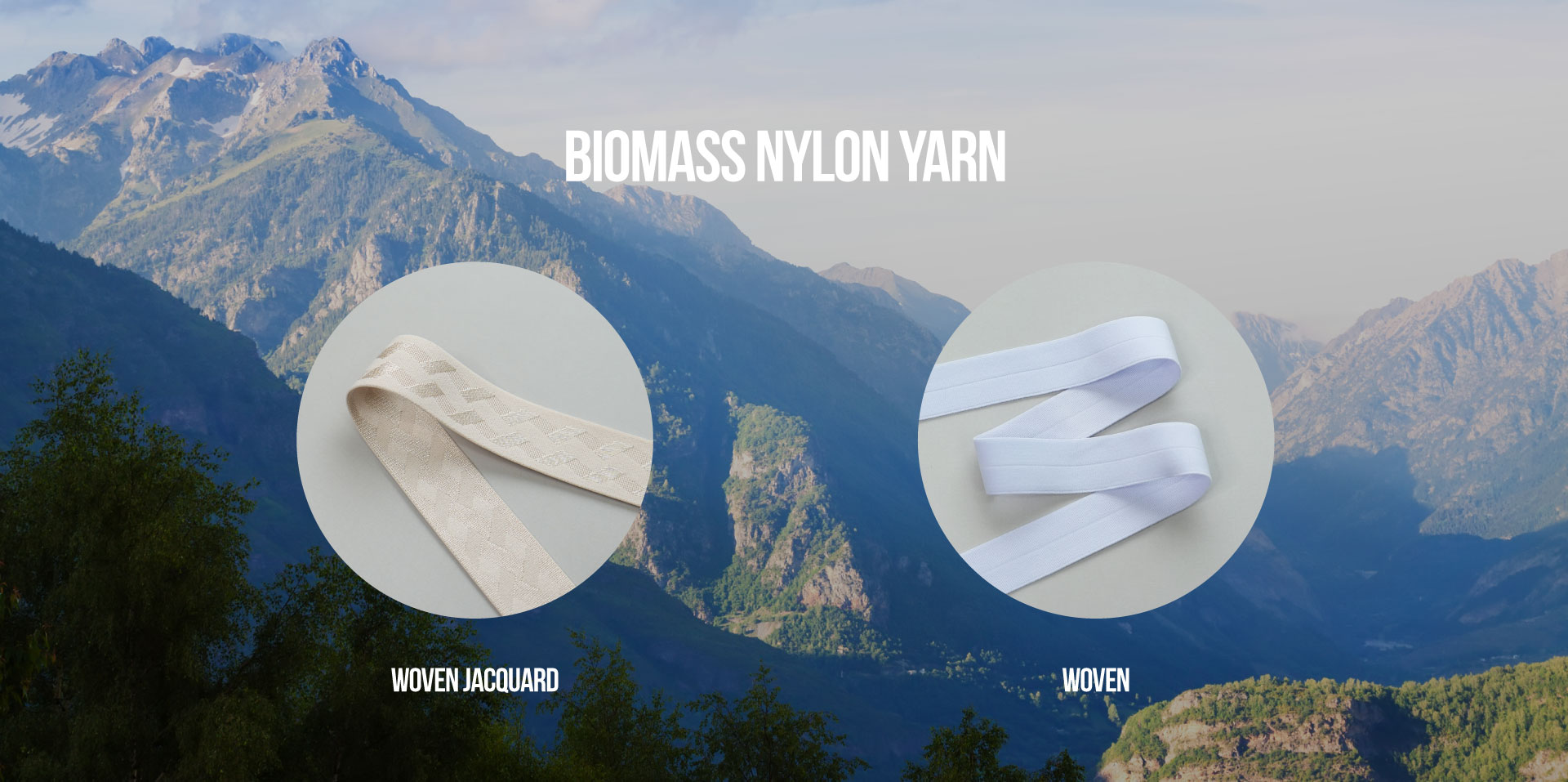

Biomass Nylon Yarn

Biomass nylon yarn, derived partly from renewable resources, offers a lower carbon footprint than conventional nylon while retaining the strength and elasticity vital for high-performance applications.

- Supplier: RUSELON

- Representative Product Items:

- Woven Jacquard: 91230-25

- Woven: 32305-20RB

By incorporating these materials into our range, we take another step toward closing the loop on textile waste and meeting consumer demand for products with reduced environmental impact.

Efficient Production Techniques

Modern production methods are another key factor in the push for sustainability. Elastic tape manufacturers are adopting more efficient processes to minimize environmental impact.

- Waterless Dyeing and Finishing: Traditional dyeing processes consume significant amounts of water and energy. New waterless technologies, such as digital dyeing, allow for vibrant colors with minimal resource usage.

- Energy-Efficient Machinery: Advanced machinery with optimized energy consumption helps reduce the carbon footprint of manufacturing operations.

- Energy Source Transition: In a significant move toward reducing our carbon footprint, ECI Elastic transitioned from coal to natural gas in our dyeing facilities in 2022. This shift not only lowers harmful environmental impacts but also contributes to a cleaner, more sustainable production process.

Through these innovations, high-performance elastic tapes can be produced responsibly, meeting both functional and environmental requirements. ECI Elastic remains committed to exploring new technologies and production methods that refine efficiency while upholding the highest quality standards.

Better Inventory Management for Reduced Waste

Sustainability doesn’t stop at production—it extends to how materials are managed and distributed. Overproduction and stockpiling can lead to unnecessary waste, a challenge elastic tape manufacturers are addressing through smarter inventory management.

- On-Demand Production: By producing elastic tapes based on specific customer orders, manufacturers can significantly reduce excess inventory.

- Predictive Analytics: Leveraging AI-driven analytics to predict demand trends ensures optimal production runs and minimizes leftover stock.

- Customizable Batch Sizes: Offering smaller, customizable production batches helps brands avoid over-ordering while still meeting their design needs.

ECI Elastic has embraced these strategies, working closely with our partners to ensure that elastic tape orders align with their actual usage, reducing waste across the supply chain.

The Road Ahead for Eco-Friendly Elastic

As 2025 unfolds, the elastic industry is at the forefront of sustainable innovation. With advancements in recycled materials, yarn development, efficient production, and inventory management, elastic tapes are transforming into eco-conscious design elements that meet the needs of modern brands and consumers.

At ECI Elastic, we remain committed to pushing the boundaries of sustainability while delivering high-quality, innovative elastic solutions. By collaborating with forward-thinking brands, we’re shaping a future where elastic tapes are as eco-friendly as they are functional and stylish.

Partnering for a Sustainable Future

Sustainability is no longer optional—it’s a necessity. The trends driving the elastic industry in 2025 reflect the broader shift toward environmental responsibility in fashion and textiles. From recycled materials to innovative production techniques, elastic tapes are leading the way in creating a greener future for apparel design.

Ready to integrate eco-friendly elastic solutions into your designs? Contact ECI Elastic today and let’s build a more sustainable tomorrow together.