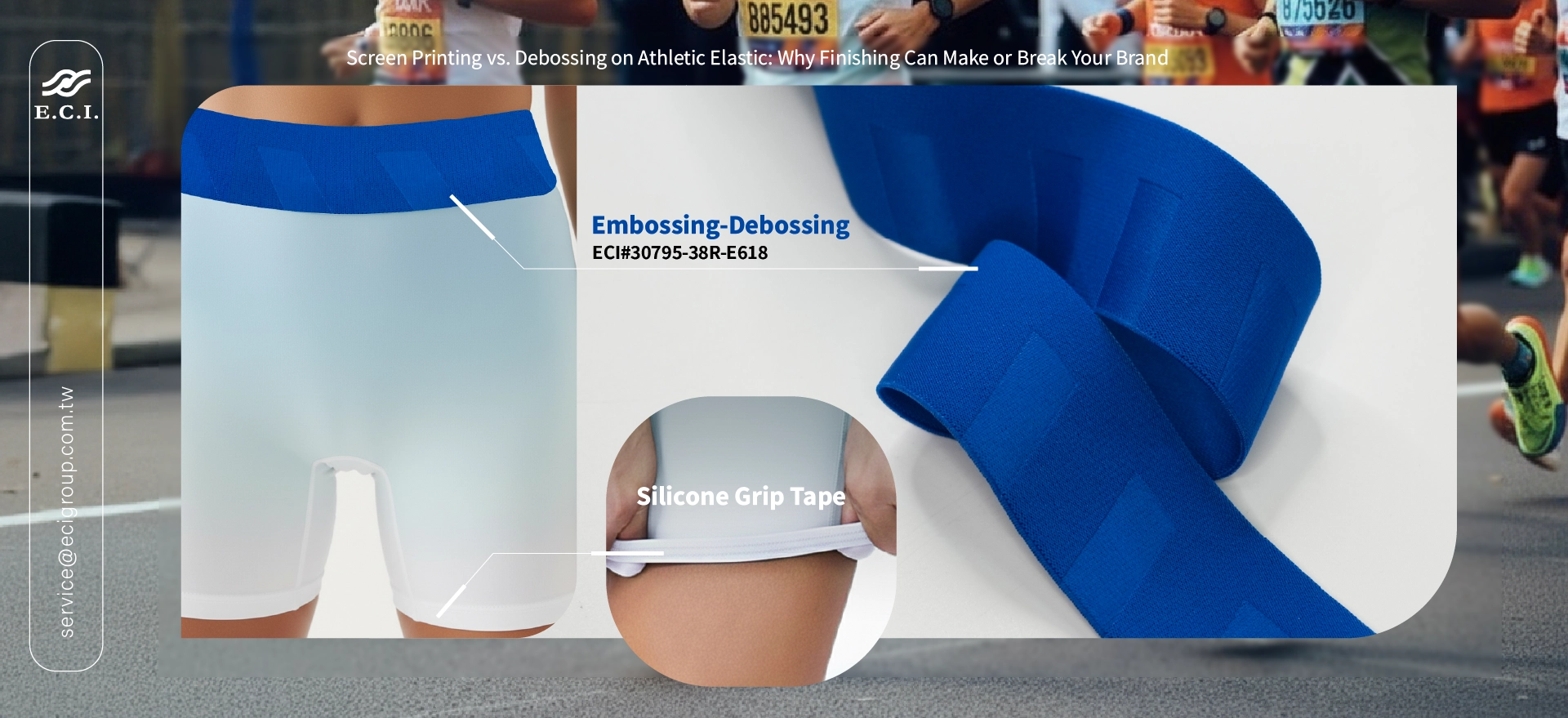

Screen Printing vs. Debossing on Athletic Elastic: Why Finishing Can Make or Break Your Brand

Today, we're explaining a small design choice that has a significant impact on how your running gear looks, feels, and holds up: screen printing vs. debossing on athletic elastic.

If you've ever wondered why one waistband displays your logo prominently while another shows it more subtly, you're already noticing the difference finishing makes. And if you're a runner, or you design for runners, finishing is the detail that separates good products from exceptional ones.

What Are These Techniques?

Screen printing puts a thin, flexible ink on top of the elastic. It's how you get bright, high-contrast logos or patterns that stand out on back neck tape, waistbands, headbands, cuffs, and more.

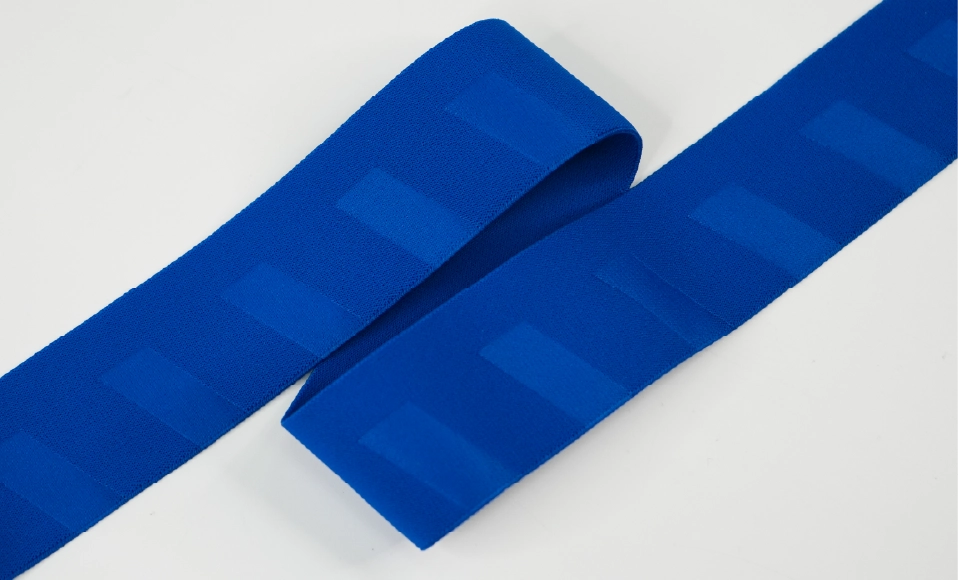

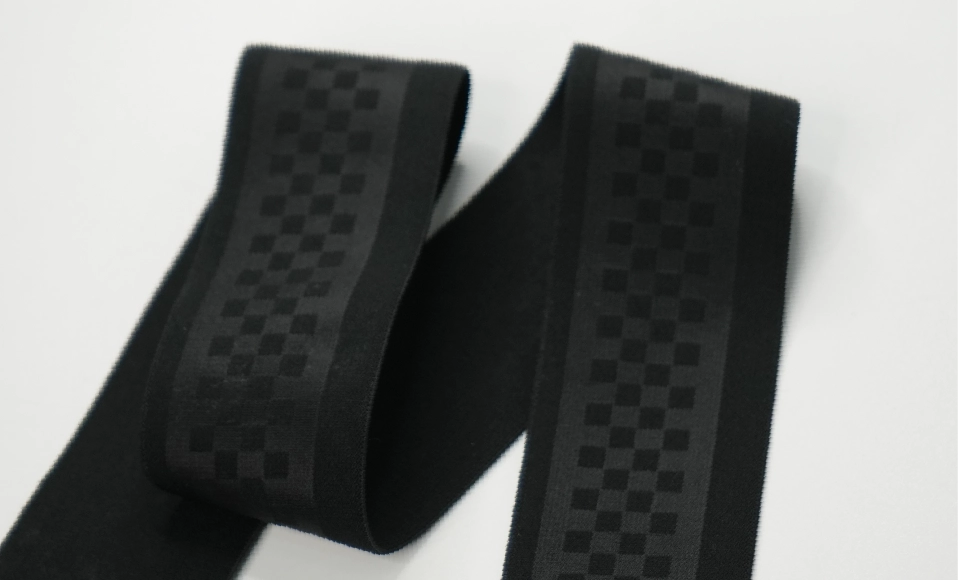

Debossing uses heated molding plates to press patterns onto the elastic, leaving a recessed, tone-on-tone mark with no added color. The result is texture rather than paint: subtle, tactile, and premium-looking.

Both techniques are reliable methods in performance apparel. They just tell different style stories—and behave differently once sweat, stretch, and washing cycles get involved.

Appearance & Hand-Feel: High-Visibility vs. Subtle Branding

Screen printing is your choice for visibility. Want a white logo that contrasts sharply on black elastic? Bright team colors wrapping a headband? Printing delivers immediate visual impact with a smooth, flexible feel. Use it when you need instant recognition: race day, team uniforms, social media product photography, or retail displays that need to catch attention quickly. In addition, silicone screen printing can produce transparent and glossy pattern effects. When combined with color, it enhances vibrancy, depth, and a three-dimensional appearance.

Debossing is the understated luxury option. The design is the same color as the elastic, made visible through light and shadow. It communicates attention to detail without bold statements. Runners who prefer minimal branding and designers building elevated athletic wear lines appreciate this look. It also appeals to those who value texture: you can feel the precision of the design with your fingers.

Performance Testing: Stretch, Sweat, and Washing

Runners are extremely demanding on elastic components. We bend, sprint, launder, and repeat.

Stretch: Modern stretch inks are engineered to flex and recover with the elastic. A well-printed logo won't crack when that waistband stretches, provided we specify the right ink and cure it properly. This means the ink formulation must be compatible with the elastic's stretch capacity, and the curing temperature and time must be precisely controlled. Debossing also tolerates stretch well, but very fine details can appear less defined at full extension, so designs should be slightly bolder. Our rule: let texture communicate the design; don't rely on extremely thin lines that may blur when stretched.

Sweat: Screen prints create a thin film on the elastic surface. On small logos, breathability stays high; on large coverage areas, breathability can decrease slightly because the ink layer blocks some air flow through the fabric. Debossing adds zero material, so the elastic's breathability remains completely unchanged. When cured or pressed correctly, neither method should bleed color or become sticky when exposed to moisture.

Washing: Both methods can be exceptionally durable. A quality print can handle dozens of washes without peeling or fading; debossing cannot peel or fade because there's no ink to wear away. General care recommendations (wash in cool water, avoid high-heat dryers) help preserve the elastic itself more than the finish.

How Small Details Shape Brand Identity

This is where finishing becomes a branding tool.

Screen printing creates an expressive, energetic, athletic impression. It's direct and bold. This method is perfect when you want color combinations, team identity, or social media product images that communicate instantly. Customers associate visible printed logos with active sportswear and performance gear.

Debossing creates a refined, modern, premium impression. It suggests sophistication and restraint. This method is perfect when you want elevated minimalism, a technical-meets-luxury aesthetic, or a clean, high-end appearance across a performance line. Customers associate subtle debossed details with premium quality and thoughtful design.

Many of our partners organize their product lines using finishing techniques: core range uses printed graphics for visual impact; premium collections use debossed details for understated elegance. Same performance level, two distinct brand identities.

Cost & Production Considerations

Screen printing:

- Low setup cost (screens are inexpensive to create), fast to test new designs and scale production

- Can produce single or multi-color designs; roll-to-roll printing options improve efficiency for larger orders

- Works well for small minimum order quantities and tight timelines

- Ideal for brands testing new designs or running seasonal collections, since design changes don't require expensive new tooling

Debossing:

- Requires a custom steel die (one-time tooling investment), slower production speed per unit

- Works best on smoother elastic surfaces; we adjust heat and pressure settings for crisp depth based on the specific elastic

- Typically suited for higher production volumes or premium price points where the subtle luxury is part of the product's value. The upfront die investment is recovered when producing larger quantities, and the die can be reused for future production runs.

Best Applications for Each Method

Waistbands (shorts, tights): Screen printing works well for bold, contrast logos or size markers because the ink layer creates sharp visual separation that's easy to see during activity. Debossing is excellent for tonal logos or continuous textures (for example, a micro-grid pattern wrapping 360° around the waistband) because the recessed pattern creates sophisticated shadow definition without competing colors.

Headbands / sweatbands: Screen printing provides visibility in race photos and video content. Debossing, on the other hand, preserves texture, reduces ink coverage, and makes the material more breathable, combining both tactile quality and practicality.

Back neck tape, cuffs & leg grippers: Printing requires a thin ink deposit to retain the elastic's natural stretch. For durability and subtlety, debossing is an excellent option.

Pockets, accessories, toggles with elastic trims: Screen printing can coordinate with color accents used elsewhere on the garment, creating visual consistency. Debossing keeps the detail cohesive in monochrome designs, maintaining a clean, unified appearance.

Common Misconceptions (And What We Actually See in Production)

"Printed logos always peel and crack." Poorly specified prints do fail. However, proper ink formulation + proper curing process + proper elastic base = no peeling. We test stretch-to-failure in our lab so your customers don't experience problems in the field.

"Debossing always distorts when stretched." Extremely fine details can appear softer at full stretch. We adapt artwork (line weight, spacing between elements) and precisely control heat and pressure for the specific elastic base. Result: crisp appearance at rest, still readable at full extension.

"Debossing is only for fashion products, not performance gear." This is incorrect. Debossing is actually an excellent performance choice when you want maximum breathability and zero risk of graphic failure. Many endurance products look better longer because there's nothing to crack, peel, or fade over time.

A Designer's Decision Guide

Do you need high-contrast color or a team palette? → Screen print. The ink layer allows you to add any color combination, creating strong visual separation.

Is the brand aesthetic minimal, tonal, or premium? → Deboss. The monochromatic, textured approach communicates refined quality (think high-end yoga wear or boutique running brands).

Will the elastic area stretch significantly (120%+) frequently? → Screen print (with stretch-engineered ink) or deboss with simplified artwork + test samples at maximum extension. Verify that the design remains legible under real-use conditions.

Is breathability in that exact zone critically important? → Deboss. Since no material is added, air flow through the elastic remains unchanged.

Tight deadline or small minimum order quantity? → Screen print. Lower setup costs and faster production make this more economical for smaller orders or quick turnarounds.

Flagship collection or statement premium piece? → Deboss. The refined appearance justifies the higher per-unit investment and communicates luxury positioning.

Design Recommendations from Our Production Team

For screen prints:

- Use vector artwork with adequate stroke width (lines that are too thin may not print clearly)

- Avoid large solid blocks if the elastic needs maximum breathability, because solid ink coverage can reduce air flow through the fabric

- Specify stretch-engineered inks that are formulated to flex with elastic

- Keep ink layers thin and ensure complete curing to prevent cracking

- Test on the actual elastic you'll use in production, not a "similar" substitute, since different elastics behave differently

For debossing:

- Use geometric patterns, repeating lines, or simple logos that read clearly through texture alone

- Avoid extremely small typography and ultra-fine details that may not press cleanly

- Plan for slightly rounded edges (the combination of metal die, heat, and fabric fibers naturally softens sharp corners)

- Preview designs at the intended stretch level to ensure readability

- Consider pairing debossing with a small printed accent elsewhere on the garment for visual interest

For both techniques:

- Prototype in the correct context—on the finished waistband circumference, over the seam location, at realistic tension

- Test on a form or person, not just flat samples. The flat sample doesn't show real-world behavior; actual wearing conditions tell the truth

Sustainability & Hand Feel

Debossing uses heat and pressure with no additional ink, making it an efficient way to add branding without extra chemicals. Screen printing, when we use modern water-based or silicone ink systems, remains highly durable and comfortable against skin. In both cases, the biggest sustainability benefit is longevity: finishes that still look good after dozens of washes keep garments in use longer, reducing replacement frequency.

Hand feel is important for athletic wear. Debossing preserves the fabric's breathability and softness completely. Screen printing can feel nearly invisible when applied in thin layers; excessive ink thickness creates a noticeable film on the surface. At ECI we aim for "you shouldn't feel it's there" unless your design specifically calls for a tactile, rubber-like texture.

Combining Both Techniques (A Popular Design Strategy)

Some of our most successful elastic trims combine both methods:

- A debossed 360° micro-pattern for visual depth, with a small printed monogram at center back for brand identification

- Exterior printed logo for visibility during activity; debossed interior size code that never washes off or fades

- Debossed tonal branding on a waistband exterior; silicone micro-dots on the interior for secure, slip-proof grip

|

Embossing-Debossing 30795-38R-E618 |

Embossing-Debossing 30795-45R-E619 |

|

|

|

|

Embossing-Debossing 31677-35P-E622 |

Screen Printing 31795-25R-S10044 |

|

|

|

|

Screen Printing 31795-50R-S6081 |

Screen Printing 31906-38-S6066 |

|

|

|

|

Screen Printing 72180-38R-S10052 |

Screen Printing 78194-22R-S10051 |

|

|

|

Summary

Print when you want: color, visibility, and speed to market.

Deboss when you want: texture, subtlety, and permanent branding that cannot fade.

Both methods can meet the demands of running: sweat, stretch, wash, repeat.

The right choice is the one that matches your brand identity and the product's intended use.

If you're unsure which method to choose, send us your design concepts and a brief description of your product goals. We'll create samples of both techniques on the actual elastic you plan to use, and let the physical samples guide the decision.

Need Help Deciding for Your Next Product?

As a vertically integrated manufacturer, we control weaving/knitting → dyeing → finishing → packaging in-house. That means we can optimize base construction and finishing together to achieve the aesthetics, comfort, and durability you want, without coordinating between multiple suppliers.

Contact us with your artwork, target price point, and a few photos of the garment. We'll recommend screen printing, debossing, or a strategic hybrid approach—and support it with samples that perform under real conditions.