Shoelaces: The Complete Guide for Footwear Brands

Shoelaces might seem like an afterthought in footwear design, but they're one of the first components users interact with, and one of the most frequent failure points. A premium running shoe with laces that fray after three weeks undermines your brand's quality message. A hiking boot with laces that won't stay tied becomes a safety issue on the trail. At ECI Elastic, we engineer shoelaces as performance components, not accessories.

Shoelaces might seem like an afterthought in footwear design, but they're one of the first components users interact with, and one of the most frequent failure points. A premium running shoe with laces that fray after three weeks undermines your brand's quality message. A hiking boot with laces that won't stay tied becomes a safety issue on the trail. At ECI Elastic, we engineer shoelaces as performance components, not accessories.

Why Shoelaces Matter

First impression: Laces are visible in every product photo, on every retail shelf, and in every unboxing video. Their texture, finish, and how they lay across the vamp create immediate visual impact.

User interaction: Laces are touched and adjusted multiple times per wear. They're one of the few components users physically engage with every time they use your product.

Performance component: In athletic and outdoor footwear, laces must maintain tension through dynamic movement, resist abrasion from eyelets and terrain, and withstand sweat, water, and temperature extremes.

Failure visibility: When a shoelace breaks or frays, the failure is immediate and obvious. Unlike a midsole that gradually compresses, lace failure creates an instant negative brand moment.

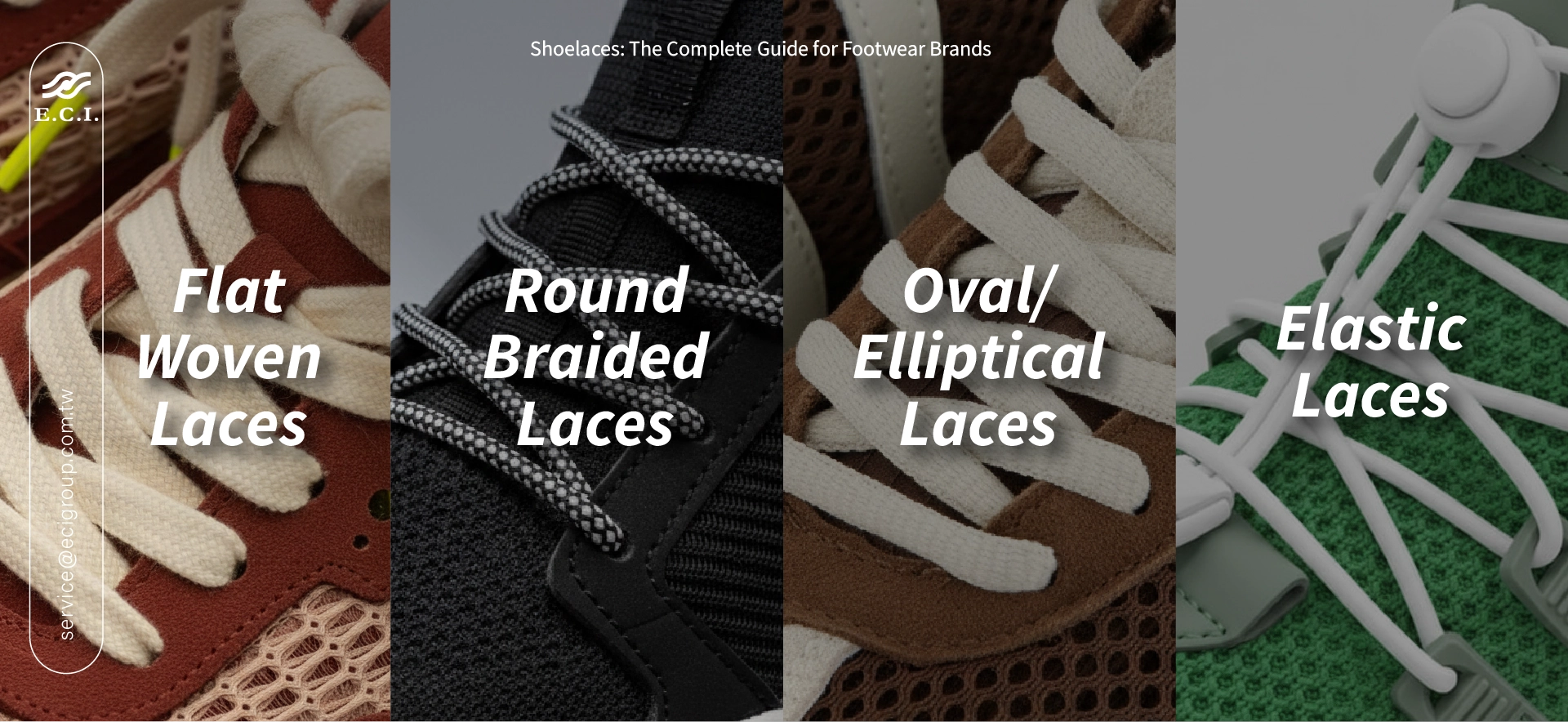

Shoelace Construction Types

Flat Woven Laces: Constructed on narrow weaving looms, flat laces offer a smooth, ribbon-like appearance. They lay flat across the vamp and through eyelets, creating clean visual lines. Best for lifestyle sneakers, casual footwear, and skate shoes. They stay tied well but can twist during lacing if not properly tensioned.

Round Braided Laces: Multiple strands braided in a tubular structure create a rope-like lace with consistent diameter. Best for hiking boots, work boots, and dress shoes. They're strong, durable, and resist flattening, though they can be bulkier through small eyelets.

Oval/Elliptical Laces: Flattened tubular construction combines benefits of round and flat laces. Ideal for running shoes and technical footwear, they stay in place better than round laces with less twist than flat laces.

Elastic Laces: Laces with integrated elastic stretch, sometimes with locking mechanisms instead of traditional bow tying. Perfect for triathlon shoes, kids' footwear, and adaptive applications. They offer no-tie convenience and accommodate foot swelling, but must maintain tension without being restrictive.

Material Compositions & Performance

Polyester: The most common lace material, offering excellent color retention, abrasion resistance, and durability at accessible price points. Polyester resists moisture, dries quickly, has minimal stretch, and takes dye well for vibrant colors.

Nylon: Slightly more durable than polyester with superior strength-to-weight ratio and excellent abrasion resistance. Ideal for high-friction applications like hiking and work boots, though it can be more slippery.

Spun Polyester: Similar to natural fiber offering soft hand feel and traditional aesthetic. Best for casual and lifestyle footwear, spun polyester provides comfortable grip and good handfeel.

Blended Compositions: Polyester/elastane or nylon/elastane blends combine benefits of multiple fibers—softer feel with improved durability, or controlled stretch for comfort without loss of support.

Specialized Materials:Reflective-integrated for visibility in running shoes, and recycled polyester for sustainability-focused brands.

Tip (Aglet) Design & Functionality

The aglet (lace tip) must allow smooth threading through eyelets, protect the lace end from fraying, and reinforce the lace under pulling stress.

Metal Aglets: Made from aluminum, brass, or stainless steel with finishes including polished, brushed, painted, or laser-etched logos. They offer premium feel and high customization but can corrode in harsh conditions and add weight.

Plastic Aglets: Lightweight, corrosion-proof, and cost-effective options available in wide color ranges with printed logos. Best for athletic and casual footwear, though less premium in perception.

Acetate Film-Free Drawcord Tips: Traditional acetate-tipped cords are durable—but create mixed-material waste. Our new Film-Free Drawcord Tipping eliminates acetate entirely, using a heat-press method with bluesign®-certified resins. The result: a mono-material drawcord that looks and performs like standard solutions, but is fully recyclable and cuts plastic waste.

Heat-Sealed Tips: Lace ends cut and heat-sealed create a stiffened tip without separate aglet hardware. This seamless look works well for minimalist designs and technical footwear.

Molded Tips: Plastic or rubber molded directly onto lace ends can incorporate brand logos or functional features, creating unique shapes and integrated branding.

Finishing Options & Customization

Printed Patterns: Screen printing or sublimation adds logos, text, patterns, or graphics for high visual impact and brand storytelling. Print durability must match lace lifespan.

Reflective Elements: Reflective yarn woven into construction or applied to the surface improves visibility in low light. Options include full reflective, reflective stripes, or reflective logos.

Multi-Color Weaving: Different colored yarns create stripes, chevrons, gradients, or complex designs. This provides distinctive looks with no print to wear off, though more complex weaving increases cost.

Shoelace Applications by Footwear Category

Running Shoes: Flat woven or oval laces, 120-140 cm, in polyester or polyester/elastane blends. Critical factors include staying tied during dynamic movement, moisture-wicking, and quick-drying properties. Reflective elements add safety for low-light conditions.

Hiking Boots: Round braided or heavy-duty flat laces, 150-200 cm, in nylon materials. High breaking strength, and water resistance are essential. Must maintain excellent knot retention and durability against rough terrain.

Lifestyle/Fashion Sneakers: Flat woven laces with varied widths, 100-140 cm, in polyester or spun polyester blends. Focus on visual impact, brand expression, custom colors, patterns, premium aglets, and coordinated aesthetics with the shoe design.

Work Boots: Round braided heavy-duty laces, 180-210 cm, in high-tenacity polyester . Features include high breaking strength, chemical resistance, and must meet safety compliance standards with reliable knot retention.

Kids' Footwear: Elastic or standard flat/round laces, 80-110 cm, in easy-care polyester. Bright colors, fun patterns, and elastic no-tie options provide durability against rough use while being easy for children to manage.

Performance Testing Standards

At ECI, we test shoelaces to ensure they meet application demands:

Tensile Strength Testing: Running/athletic shoes require minimum 50 kg breaking strength; work boots and hiking require minimum 80 kg (GB/T 36975-2018)

Abrasion Resistance: Laces undergo Martindale or Taber testing for thousands of cycles, simulating friction against eyelets and external surfaces. (ASTM D3389 / D3884 / D3385)

Colorfastness: ISO 105 testing verifies color stability against light exposure, washing, and perspiration with target grades of 4-5 (minimal to no color change).

Knot Retention: Laces must stay tied through 1,000+ movement cycles under dynamic loading.(ISO 20344)

Wash Durability: Industrial wash testing confirms laces maintain integrity, color, and appearance through 50+ cycles.

Sustainability Considerations

ECI offers shoelaces made from GRS-certified recycled polyester, reducing reliance on virgin materials while maintaining performance standards. Our engineering focus on durability means laces that last the lifetime of the shoe, eliminating replacement needs and reducing waste.

Film-Free Tipping Technology: Traditional acetate-tipped laces create mixed-material waste that complicates recycling. ECI's innovative film-free drawcord tipping eliminates acetate entirely, using a heat-press method with bluesign®-certified resins. This creates fully recyclable mono-material laces that cut plastic waste by 15–20% while maintaining the look and performance of standard solutions.

We optimize production processes to minimize material waste and use water-based dyes and finishes to reduce environmental impact. Single-material laces are easier to recycle, and we can engineer specifications that align with your circularity goals.

Custom Shoelace Development at ECI

Our process begins with requirements definition—understanding your footwear type, performance requirements, aesthetic goals, and target price point. We recommend optimal lace type, material composition, and finishing based on these requirements. Color matching, aglet selection, and special features are specified, followed by prototype development and testing on your actual footwear.

Performance testing includes tensile strength, abrasion, colorfastness, and wash durability. Production includes in-line quality checks with every batch tested for consistency. Laces are packaged per your specifications: bulk rolls, pre-cut pairs, or retail-ready packaging.

Why Choose ECI for Shoelace Manufacturing

Vertical Integration: We control the entire process from yarn production through weaving, dyeing, finishing, and aglet attachment, ensuring consistent quality and customization at every stage.

Technical Expertise: Our product development team collaborates to optimize lace performance for your specific application, not just manufacture to spec.

Quality Systems: ISO-certified production with comprehensive testing protocols ensures every batch meets strength, colorfastness, and appearance standards.

Customization Capabilities: In-house printing, reflective integration, custom aglet tooling, and specialized finishing provide complete solutions.

Global Scale, Local Partnership: Production capacity supports brands from startup sampling through global distribution with responsive communication and technical support.

Final Thought

Shoelaces are the handshake between your customer and your product. Every time users lace up, they're interacting with your brand. A lace that performs flawlessly becomes invisible, which is exactly what you want. A lace that fails becomes a lasting negative memory.

At ECI Elastic, we engineer shoelaces that disappear into the user experience while elevating your product's performance and appearance. Because the details that seem small are often the ones customers remember most.

Ready to develop custom shoelaces for your next footwear collection? Contact our footwear development team with your product specifications, performance goals, and aesthetic vision.