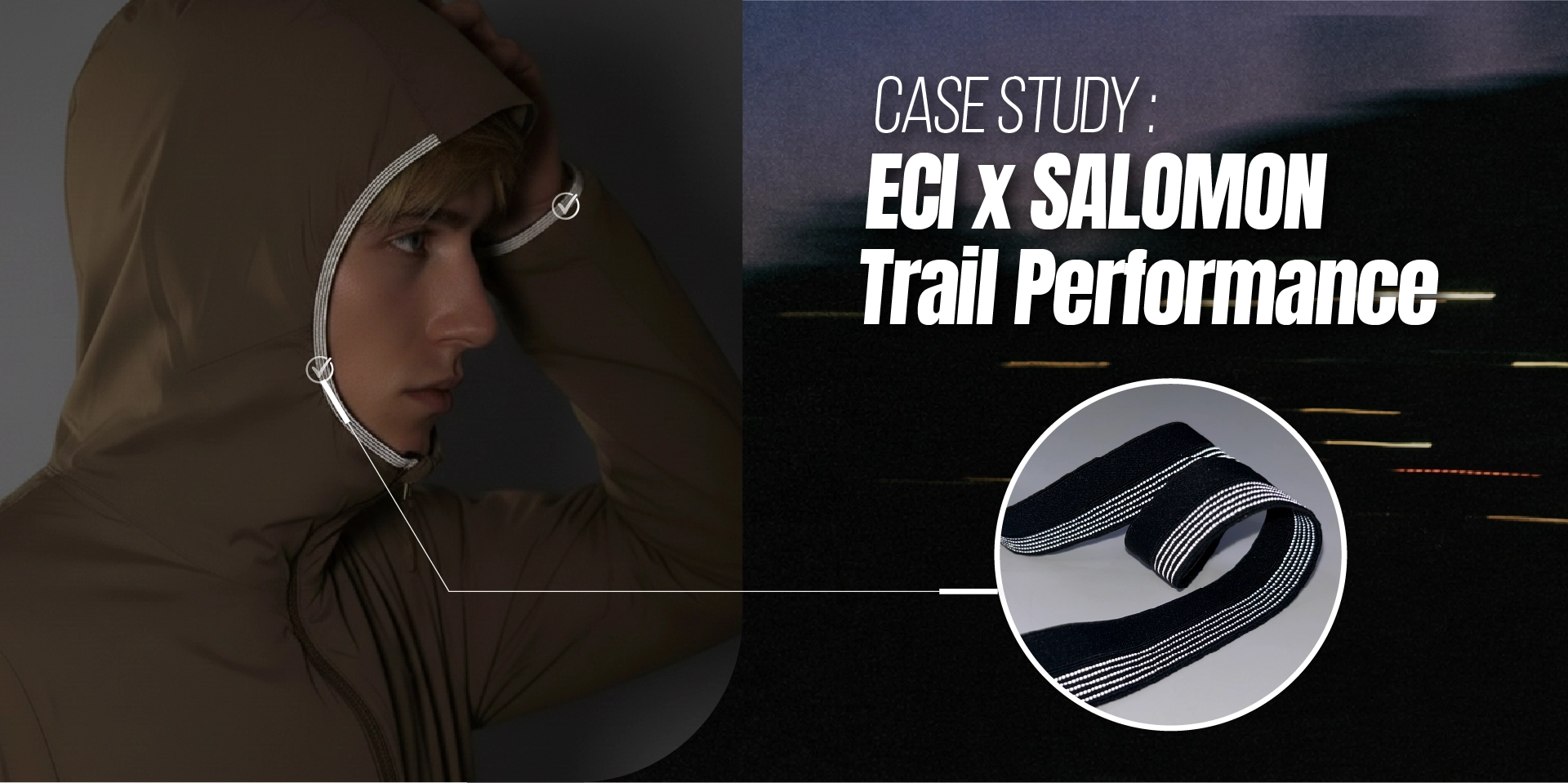

Case Study:ECI x SALOMON Trail Performance

When Visibility Becomes Structure: How ECI's Reflective Binding Redefined Safety and Craftsmanship

Built for the Trail, Engineered for the Night

The trail doesn't end at sunset. For SALOMON, the global leader in mountain sports, creating gear for runners and hikers means designing for every condition—including the moment when daylight fades and visibility becomes survival.

The challenge: develop a reflective solution that doesn't compromise after months of use, hundreds of washes, or thousands of kilometers. SALOMON needed more than bright tape—they needed a safety system woven into the very structure of their garments.

To meet this standard, SALOMON partnered with ECI to develop a reflective binding tape that would redefine what durability and visibility could mean together.

The Durability Question: Why Materials Matter More Than Brightness Alone

In reflective performance, how reflectivity is achieved determines how long it lasts. The market offers two primary approaches: reflective films and reflective yarns—and their performance differs dramatically under real-world conditions.

Reflective films are applied to fabrics through heat transfer or lamination. While they deliver impressive initial brightness, outdoor use reveals critical vulnerabilities. Film-based solutions face inherent limitations: they cannot stretch with elastic materials, creating stress concentrations that cause edge lifting, cracking, and eventual peeling. Repeated washing, abrasion, and thermal cycles accelerate degradation. In high-movement applications—precisely where outdoor athletes need them most—films prove fundamentally incompatible with garment demands.

Reflective yarns take a different approach entirely. Woven directly into the binding tape structure, they move with the fabric, enduring the same stretching and washing cycles as the base material. This structural integration delivers clear advantages in longevity and sustained performance—advantages that become increasingly apparent with each wear and wash.

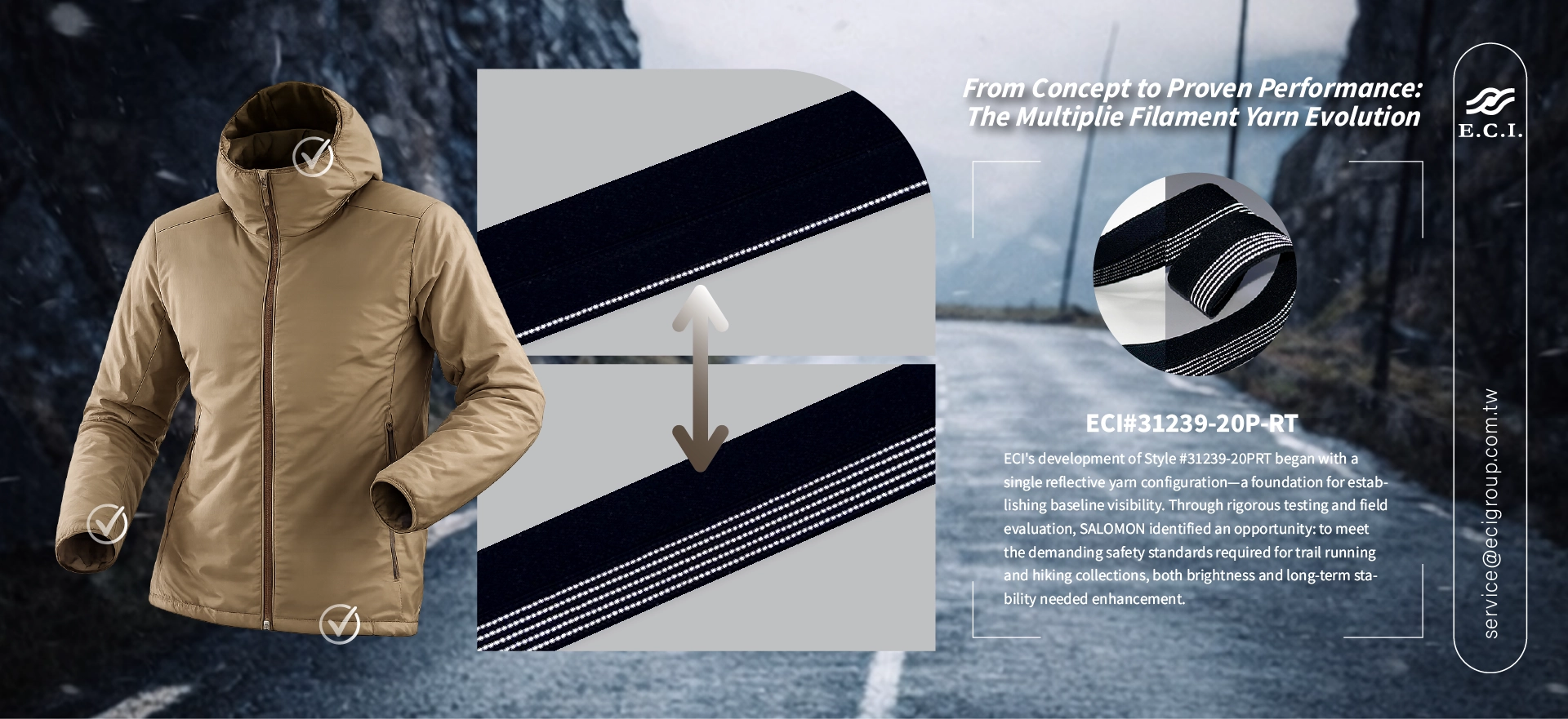

From Concept to Proven Performance: The Multiplie Filament Yarn Evolution

ECI's development of Style ECI#31239-20P-RT began with a single reflective yarn configuration—a foundation for establishing baseline visibility. Through rigorous testing and field evaluation, SALOMON identified an opportunity: to meet the demanding safety standards required for trail running and hiking collections, both brightness and long-term stability needed enhancement.

The solution emerged through close collaboration between ECI and SALOMON engineering teams. The design evolved to incorporate five reflective yarns—a strategic upgrade that expanded reflective surface area through woven structure rather than surface treatment. The result: more concentrated reflectivity, wider reflection angles, and consistent performance that survives prolonged use and repeated washing.

Reflective yarns carry higher material costs than films. But their durability and stability throughout the product lifecycle deliver exponentially greater value—effectively eliminating performance degradation risks while meeting SALOMON's exacting standards for high-performance outdoor equipment.

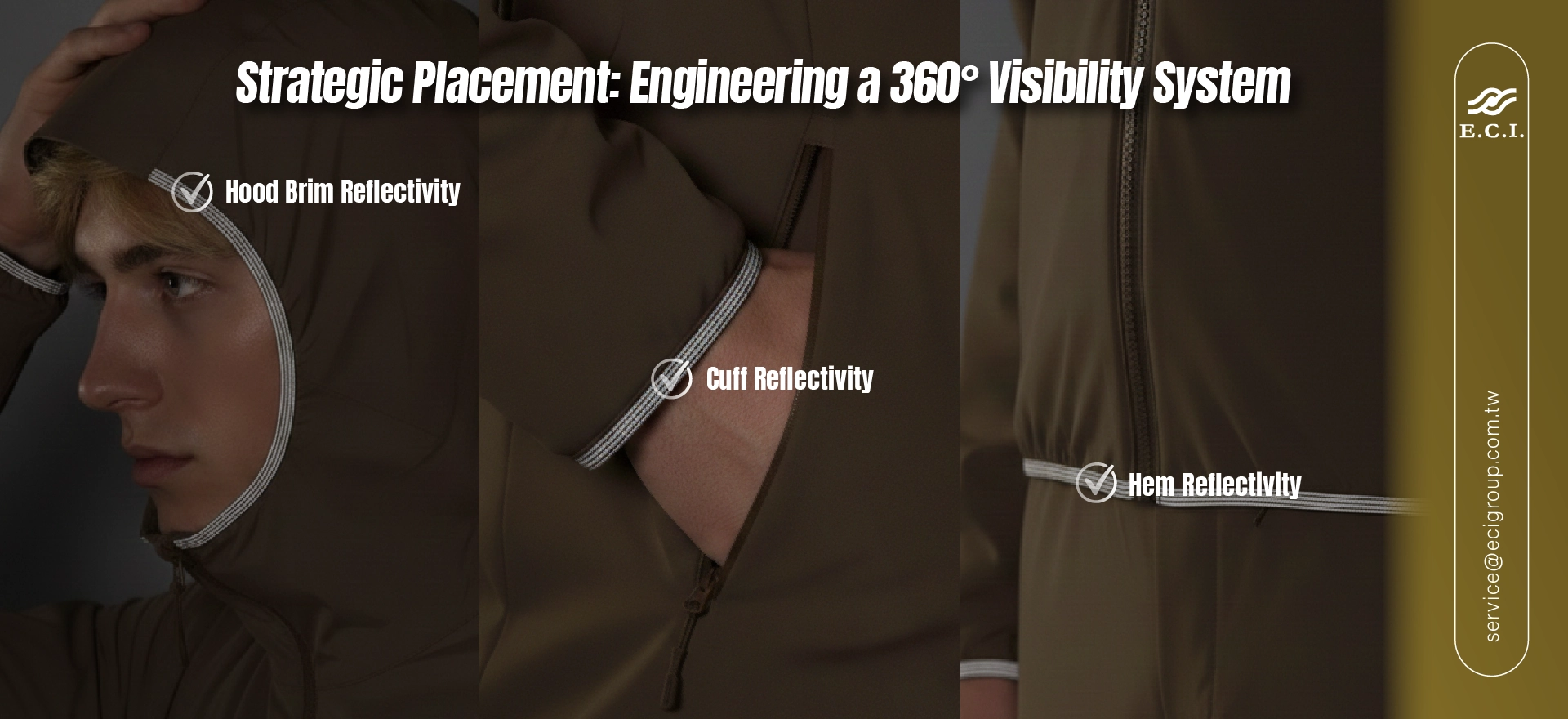

Strategic Placement: Engineering a 360° Visibility System

In SALOMON's product architecture, ECI's reflective binding tape appears at three critical locations, creating a comprehensive safety visibility framework:

- Hood Brim Reflectivity — Enhances frontal visibility while reinforcing brand recognition and design precision.

- Cuff Reflectivity — Provides dynamic, motion-based reflection that increases night visibility during arm movement.

- Hem Reflectivity — Establishes a stable visual reference line for consistent safety awareness from rear and side angles.

Together, these placements form a 360° visibility perimeter—a complete solution addressing real-world safety requirements across diverse outdoor activity scenarios.

Beyond Visibility: The Structural Value of Binding Integration

ECI#31239-20P-RT delivers more than reflective performance. As a binding tape, it fulfills essential structural functions that elevate overall garment quality:

Reinforcing fabric edges and seam strength to withstand stress and movement. Reducing curling, fraying, and long-term wear at high-contact zones. Improving durability in areas subject to repeated motion and environmental exposure. Enhancing garment precision through refined edge finishing and clean construction details.

This dual functionality transforms reflective binding tape from safety accessory to integrated component—where safety, structure, and craftsmanship converge in a single solution.

Designed for Demanding Applications

ECI#31239-20P-RT proves particularly effective across performance outdoor categories:

- Trail running jackets and technical outerwear.

- Night running and layering garments for urban and mountain environments.

- Hiking functional apparel requiring extended durability.

- Urban outdoor collections balancing style with safety features.

- Lightweight, high-performance sportswear where weight and function must coexist.

Its combination of reflective brightness, elastic recovery, post-wash stability, and edge-binding performance meets the rigorous durability and safety standards expected by leading international outdoor brands.

The Long-Term Safety Equation: Integration Over Application

Reflective designs engineered for high-performance outdoor use must transcend short-term brightness. True effectiveness requires surviving prolonged stretching, repeated washing, and years of real-world conditions—precisely the demands where film-based solutions falter and yarn-based integration excels.

This SALOMON collaboration demonstrates a clear principle: while reflective yarns involve higher initial investment, they deliver superior long-term value in both durability and sustained safety performance. By weaving reflective yarns directly into binding tape structure, ECI achieved an optimal balance—safety that lasts as long as the garment itself.