Shoelaces Manufacturer

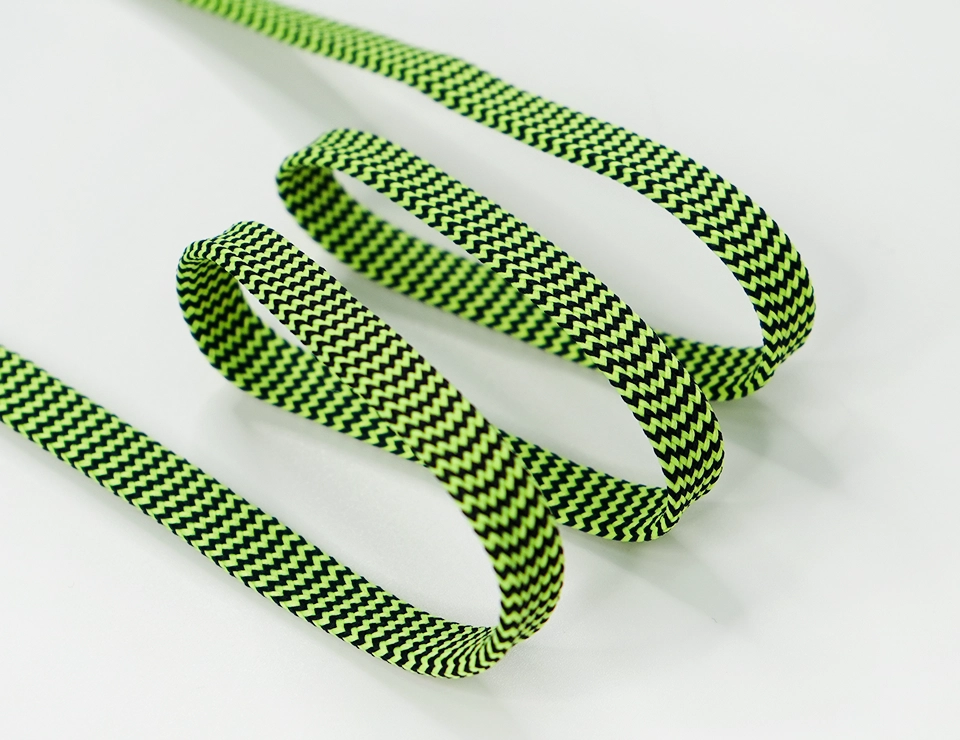

Shoelaces are a critical touchpoint—touched, adjusted, and visible every time the shoe is worn. As a leading shoelaces manufacturer, we provide high-quality custom shoelaces in flat, round, oval, and elastic constructions, combining durability, stretch recovery, and aesthetic appeal for athletic, casual, and performance footwear. Our custom shoelaces are available in a variety of widths, colors, aglet styles, reflective yarns, GRS-certified recycled materials, and film-free tipping for fully recyclable mono-material laces. Standard and fully custom designs are available to meet the needs of global footwear brands.

Wholesale Shoelace Manufacturing

As a vertically integrated shoelace manufacturer, we control every step of production, from yarn selection through weaving, braiding, dyeing, finishing, and aglet attachment. Our wholesale shoelace supply capabilities serve footwear brands of all sizes, from startup labels to global athletic companies. We use advanced looms and precise quality-control systems to ensure each shoelace meets strict strength, colorfastness, and appearance standards. Our product development teams work closely with customers to develop customized laces that align with specific footwear requirements, including construction type, aglet style, reflective elements, and branding placement.

Technical Specifications

We offer a variety of specification options to meet your specific needs. From standard to advanced custom solutions, we have the right option for you.

| Specification | Standard Range | Premium/Additional Options | Custom Available |

|---|---|---|---|

| Lace width | 5–10 mm (flat/oval) | Up to 15 mm for bold styles | Yes |

| Construction type | Flat woven, round braided | Oval, knit tubular, elastic | Yes |

| Material composition | 100% polyester | Nylon, cotton spun polyester blends, recycled polyester (GRS-certified), nylon/elastane | Yes |

| Length options | 90–150 cm for most footwear | Up to 210 cm for work boots/high-tops | Yes |

| Aglet type | Plastic acetate tip | Metal (aluminum, brass), heat-sealed, film-free sustainable tip, molded custom | Yes |

| Surface/finish | Standard smooth | Waxed, reflective yarn, printed patterns, multi-color weave | Yes |

| Branding options | Plain lace | Screen-printed logo, woven pattern, reflective branding, custom aglet engraving | Yes |

| Color options | Standard black, white, gray | Customized colors and Pantone matching | Yes |

| Minimum order | 10,000 pairs | Reduced minimums for selected styles | Negotiable |

| Lead time | 2–3 weeks | 3–4 weeks for custom colors, aglets, or branding | Longer for complex solutions |

Quality Certifications

All shoelaces are manufactured to OEKO-TEX Standard 100, ISO 9001:2015 quality management standards, and meet international textile safety standards. Laces undergo tensile strength, abrasion resistance, colorfastness, and wash durability testing to ensure performance throughout the life of the shoe.

How to Order

Our ordering process is simple and efficient, ensuring you receive quality products that meet your specifications.

Initial Consultation

Contact our sales team with your specifications, including construction type, width, length, material preferences, aglet style, and quantity estimates for a comprehensive project assessment.

Sample Development

Our engineering team creates precision prototypes based on your exact requirements, typically delivered within 14–21 business days for thorough evaluation and testing.

Material & Design Selection

Choose from our extensive range of constructions, materials, aglet configurations, and color matching services, including Pantone color matching for brand consistency.

Quote & Production Timeline

Receive detailed pricing based on specifications, quantities, and delivery requirements with transparent lead times and flexible payment terms for your business needs.

Production & Quality Control

Your order enters our ISO-certified manufacturing environment with regular quality checkpoints, progress updates, and comprehensive testing throughout the production cycle.

Top Questions About Our Shoelaces

Frequently asked questions about our products and services.

Flat woven laces work best for lifestyle sneakers, casual footwear, and skate shoes—they lay cleanly across the vamp and stay tied well. Round braided laces suit hiking boots, work boots, and dress shoes where durability and a classic aesthetic matter. Oval laces are ideal for running and training shoes, offering the stability of flat laces with less twist. Elastic laces are perfect for triathlon shoes, kids' footwear, and adaptive designs requiring no-tie convenience.

Polyester offers excellent color retention, abrasion resistance, and minimal stretch—suitable for most applications. Nylon provides superior strength and abrasion resistance, ideal for hiking and work boots. Cotton Spun polyester delivers a softer hand feel and heritage aesthetic but absorbs moisture and wears faster. Blended compositions (polyester/cotton elastane or nylon/elastane) combine benefits: softer feel with improved durability, or controlled stretch for comfort without losing support.

We offer plastic acetate tips (lightweight, wide color range), metal aglets in aluminum, brass, or stainless steel (premium feel, customizable finishes), heat-sealed tips (seamless, minimalist), and molded tips for custom shapes and integrated branding. Our film-free sustainable tips use a heat-press method with bluesign®-certified resins, eliminating acetate to create fully recyclable mono-material laces that cut plastic waste by 15–20%.

Yes. Screen printing and sublimation allow logos, text, and graphics on lace surfaces. Reflective yarn can be woven directly into the lace, or reflective ink applied via printing for low-light visibility. Multi-color weaving creates stripes, gradients, and patterns without print. Metal aglets can be laser-etched with logos; molded tips can incorporate branding. All options are tested for durability and wash resistance.

Low-top sneakers (3–4 eyelets): 90–110 cm. Mid-top sneakers (5–6 eyelets): 120–140 cm. High-tops (7–8 eyelets): 140–160 cm. Running shoes (6–7 eyelets): 120–140 cm. Hiking boots (7–9 eyelets + speed hooks): 150–180 cm. Work boots (8–10 eyelets): 180–210 cm. These are starting points—always prototype with your specific eyelet spacing and desired bow size.

Yes. We offer GRS-certified recycled polyester laces that perform identically to virgin materials. Our film-free aglet technology creates mono-material laces that are fully recyclable. We use water-based dyes and finishes where possible, and our durability focus means laces last the life of the shoe, reducing replacement waste.

All laces are tested for tensile strength (minimum 50 kg for athletic, 80 kg for work/hiking), abrasion resistance (10,000+ Martindale cycles), colorfastness to light, washing, and perspiration (ISO 105, Grade 4–5), knot retention under dynamic load, aglet pull-off strength (minimum 5 kg), and wash durability through 50+ cycles. All products meet OEKO-TEX Standard 100 and ISO 9001:2015 standards.

Ready to Start Your Project?

Contact our manufacturing experts for custom quotes and sample development. We are committed to realizing your shoelace design vision with precision engineering and excellent quality.

Get Custom Quote