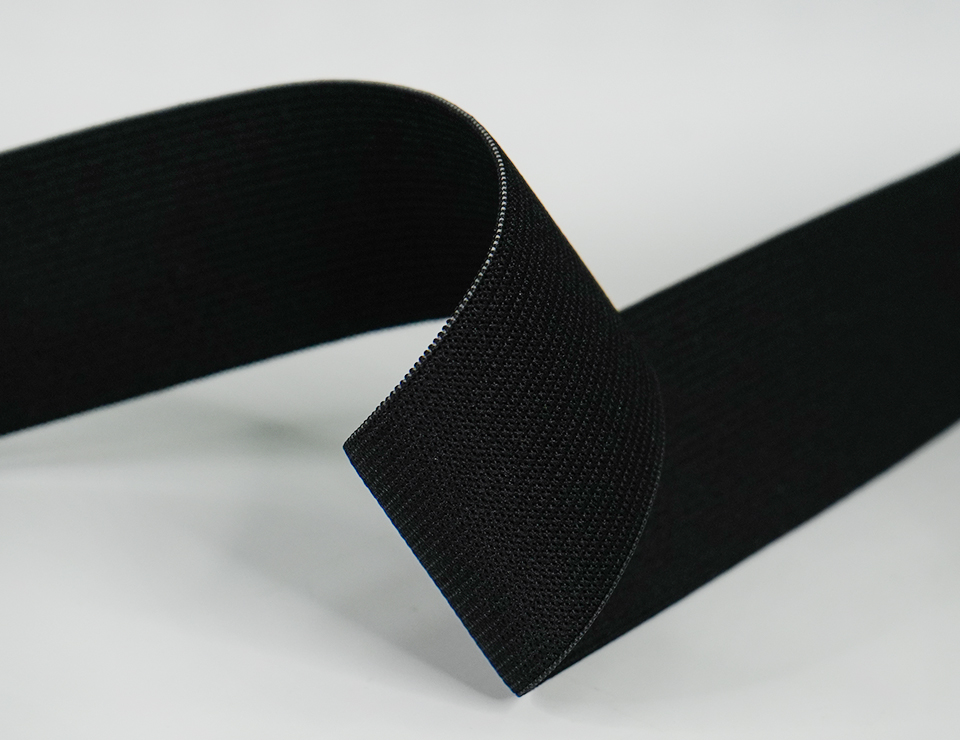

Inner Elastics

Inner elastics are versatile foundation trims that provide essential support and structure inside garments without being visible from the outside. Sewn into waistbands, sleeve hems, necklines, and leg openings, it delivers reliable stretch and recovery to maintain garment shape and ensure a comfortable, secure fit. Available in knit construction with varying elasticity levels, inner elastic is engineered for durability and performance across activewear, outerwear, and everyday apparel. Our tapes come in multiple widths and blend options to suit different garment weights and stretch requirements. From standard polyester/rubber blends to specialized formulations, we offer both stock and custom solutions tailored to your production needs

-

Inner Elastic 44641-57.15R-SP

-

Inner Elastic 44636-35R-LT

-

Inner Elastic 44638-16R-SP

-

Inner Elastic 44638-32R-SP

-

Inner Elastic 44638-22R-SP

-

Inner Elastic 44638-38R-SP

-

Inner Elastic 44642-71R-SP

-

Inner Elastic 44639-63.5R-SP

-

Inner Elastic 44637-44.5R-SP

-

Inner Elastic 44636-50R-SP

Wholesale Inner Elastic Manufacturer

As a vertically integrated inner elastic manufacturer, our production process gives us complete control over every step—from yarn selection through knitting, dyeing, finishing and packaging. We use precision knitting equipment and rigorous quality-control systems to ensure each inner elastic delivers consistent stretch, recovery, and durability. Materials are engineered to resist breakdown from repeated washing and wear. Our teams work closely with customers to develop customized elastic tapes that align with specific garment requirements, including elasticity levels, width specifications, and material blends optimized for performance.

Technical specifications

| Specification | Standard range | Premium/additional options | Custom available |

|---|---|---|---|

| Tape width | 1/4 in to 2 inches (6.4–50 mm) – the most common sizes for waistbands and openings | Narrower or wider widths for specialized applications | Yes |

| Material composition | Polyester/rubber blend | Nylon/spandex blends, natural rubber alternatives, recycled content options | Yes |

| Stretch capacity | Medium stretch (30–50%) – suitable for most apparel | High-stretch formulations (50–100%+) for performance activewear | Yes |

| Aesthetic/stability | Good stability with reliable recovery | Enhanced recovery for high-performance applications | Yes |

| Color options | Solid colors: black, white | Custom color matching | Yes |

| Minimum order | 10,000 meter | Reduced minimums for selected styles | Negotiable |

| Lead time | 2–3 weeks | 3–4 weeks for custom specifications | Longer for complex solutions |

Quality Certifications

All inner elastic tapes are manufactured to OEKO-TEX Standard 100, ISO 9001:2015 quality management standards, and meet international textile safety standards for direct skin contact applications.

How to Order

Our ordering process is simple and efficient, ensuring you receive quality products that meet your specifications.

Initial Consultation

Contact our sales team with your specifications, including width requirements, elasticity needs, material preferences, and quantity estimates for a comprehensive project assessment.

Sample Development

Our engineering team creates precision prototypes based on your exact requirements, typically delivered within 14-21 business days for thorough evaluation and testing.

Material & Design Selection

Choose from our extensive range of premium elastic blends, stretch configurations, and color matching services, including Pantone color matching for brand consistency.

Quote & Production Timeline

Receive detailed pricing based on specifications, quantities, and delivery requirements with transparent lead times and flexible payment terms for your business needs.

Production & Quality Control

Your order enters our ISO-certified manufacturing environment with regular quality checkpoints, progress updates, and comprehensive testing throughout the production cycle.

Top questions about our Inner Elastic

Polyester/rubber blends offer the best balance for most applications, combining consistent stretch with long-lasting durability. For premium performance, nylon/spandex blends provide superior elasticity and recovery, while natural rubber alternatives deliver excellent stretch for eco-conscious brands.

Wider elastic (1.5–2 inches) distributes pressure more evenly across the body, preventing pinching and improving comfort in waistbands. Narrower widths work well for sleeve hems and necklines where less grip is needed. Width also affects how securely the garment stays in place during movement.

Medium stretch (30–50%) suits everyday apparel like casual pants and skirts. High-stretch formulations (50–100%+) are essential for activewear, yoga pants, and performance sportswear where maximum movement and recovery are required. Outerwear typically uses lower-stretch options for structure.

Quality inner elastic uses high quality yarns and stabilized rubber cores that resist breakdown from laundering cycles. The proper construction allows fibers to expand and contract without losing memory. Proper material selection and finishing treatments prevent degradation, ensuring the elastic returns to its original dimensions even after hundreds of wash cycles.

Yes. We engineer custom formulations by adjusting yarn ratios, rubber content, and knit tension to achieve your target stretch percentage. Material blends can incorporate recycled polyester, specialized spandex grades, or natural rubber alternatives tailored to your garment's performance needs.

Stitching the elastic flat at multiple points (typically every few inches) prevents rotation. Using a zigzag or stretch stitch accommodates movement without breaking thread. For waistbands, encasing the elastic fully or using bar tacks at seam intersections keeps it stable. Proper width selection relative to the casing also minimizes rolling.

Yes. We offer inner elastic made with recycled polyester content and can source natural rubber alternatives that reduce environmental impact. These sustainable options maintain comparable stretch and durability to conventional materials while supporting your brand's sustainability goals.

Ready to start your project?

Contact our manufacturing experts for custom quotes and sample development. We are committed to realizing your inner elastic design vision with precision engineering and excellent quality.

Get Custom Quote